- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Planetary Ball Mill Machine

Model Number:

TMAX-DSP-LBPBM05BCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Planetary Ball Mill Machine

SPECIFICATIONS

|

Transmission |

Gear transmission |

|

Work |

two or four tanks simultaneously milling |

|

Max sample loading capacity |

2/3 of Tank volume |

|

Tank volume |

Each tank :0.05L~50L, total volume :0.2L~200L |

|

Feed size |

Soil material ≤10mm, other material ≤3mm |

|

Discharge size |

Mix 0.1um |

|

Speed ratio (revolution: Rotation) |

1:2 |

|

Speed (rotation) |

0-900 r / min (ordinary), 0-1400 rev / min (high-speed type); |

|

Velocity modulation way |

Stepless speed regulation Speed Accuracy 0.2 rev / min; |

|

Programmable control |

Ball mill using high-tech micro-computer chip control, can set the program forward and backward alternately run (0-999min) and forward, pause, reverse, pause, forward (0-999min) alternate operation, particularly suitable cooling or if you need to run it intermittently |

|

Maximum continuous working time (full load) |

72 hours (timer 0-9999h) |

|

Motor Power |

According to different device models and milling load weight, the main power is 0.55KW and 0.75KW, |

|

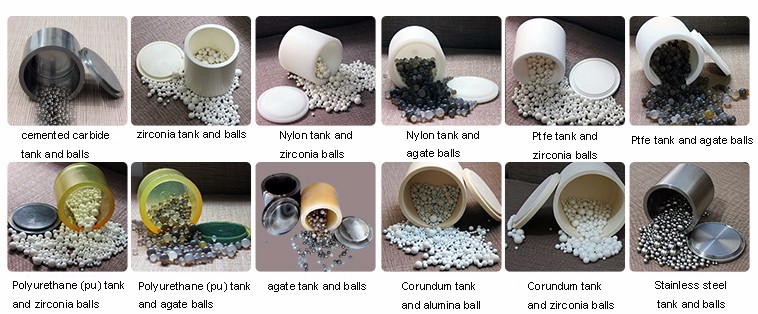

Various optional materials of milling tank |

Agate, alumina corundum ceramics, zirconia ceramics, silicon nitride ceramic, silicon carbide ceramic, stainless steel, high wear-resistant steel, manganese steel, nylon, PTFE, polyurethane, carbide, crystal glass, and other special metal materials and so on; |

|

Optional milling media |

Agate, alumina, zirconia, silicon nitride, silicon carbide, stainless steel, high wear-resistant steel, manganese steel, nylon, polyurethane, carbide, glass, and other special metals, etc. |

|

Optional milling environmental conditions |

Vacuum ball milling, the inert gas milling, cold milling, ball milling high temperature |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com