- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Small Tonnage Automatic Powder Hydraulic Press

Model Number:

TMAX-PP-2SDimension(L*W*H):

245*245*450(mm)Net Weight:

50kgCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportDelivery Time:

3 Days

Small Tonnage Automatic Powder Hydraulic Press

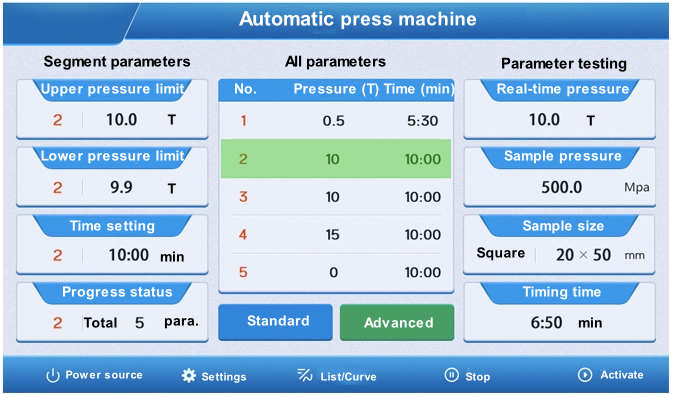

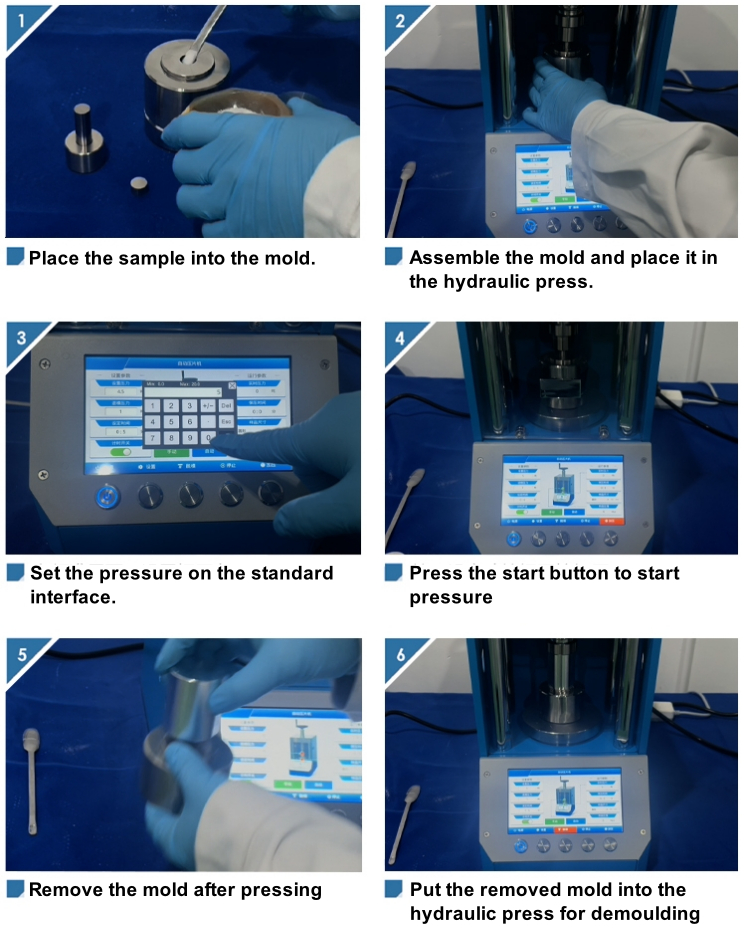

Operation interface (Standard mode)

Standard interface: Various parameters such as pressure, demoulding, time, sample size, etc. can be set in this interface alone.

Pressurization button: Press according to the parameters set on the interface.

Stop button: Press the stop button during the pressurization process to stop the pressurization.

Demoulding button: Press the demoulding button to release the sample according to the demoulding pressure.

Timing switch: The timing function can be turned on and off.

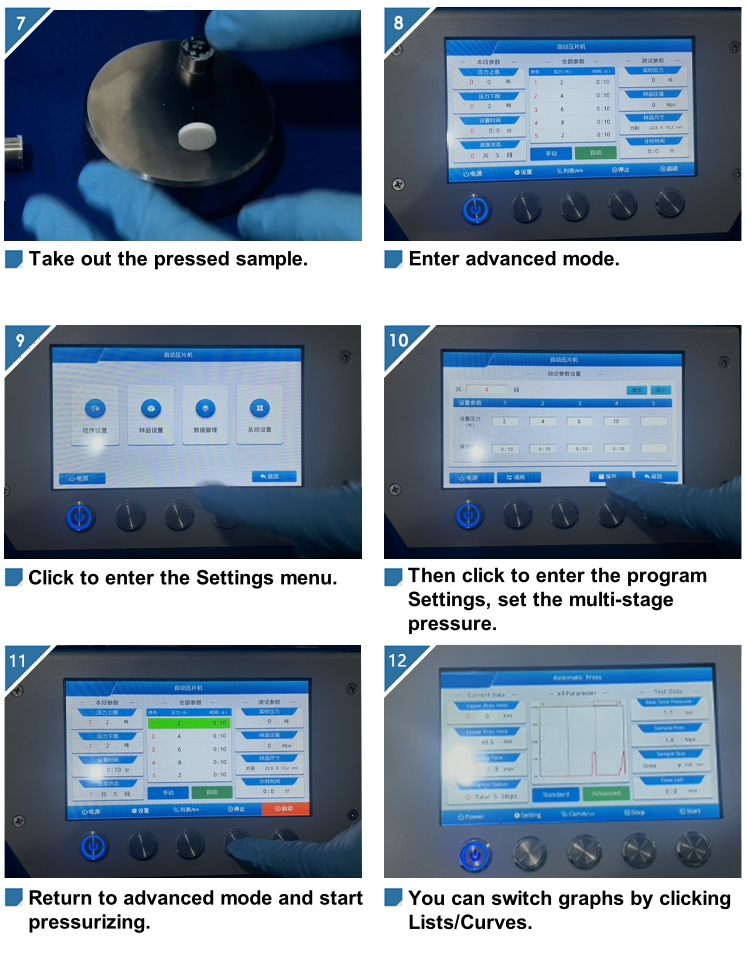

Operation interface (Advanced mode)

Activate button: Can be pressed according to the multi-stage pressurization program.

Stop button: Press the stop button during the pressurization process to stop the pressurization.

Setting button: Click the Settings button to enter the Settings menu.

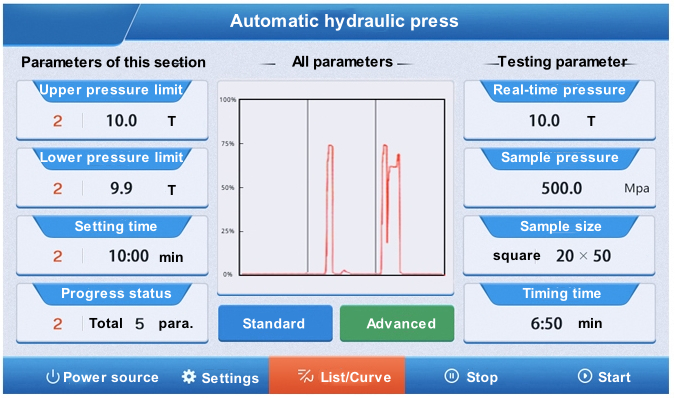

Operation interface (Advanced mode)

List/Curve: The current display state can be switched between list and curve.

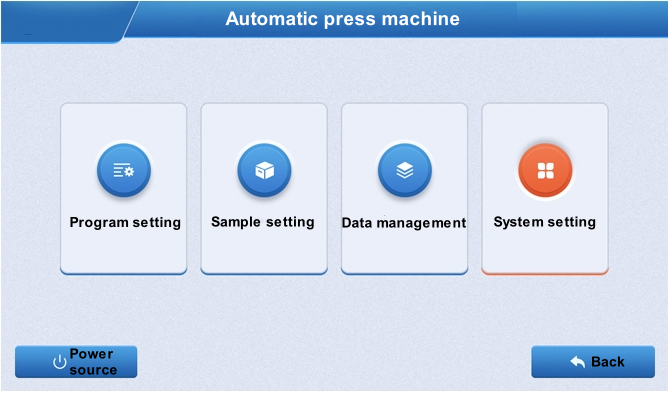

Setting interface

Tap Settings on the operation screen to enter the Settings screen. The Settings screen has four ICONS.

Program Settings: Multi-stage pressure program and pressure holding time can be set.

Sample settings: The shape and size of the sample can be set to facilitate the user to calculate the pressure of the sample.

Data management: Previously saved data records can be invoked and modified.

System Settings: Administrators can set various parameters, enter the password "666"

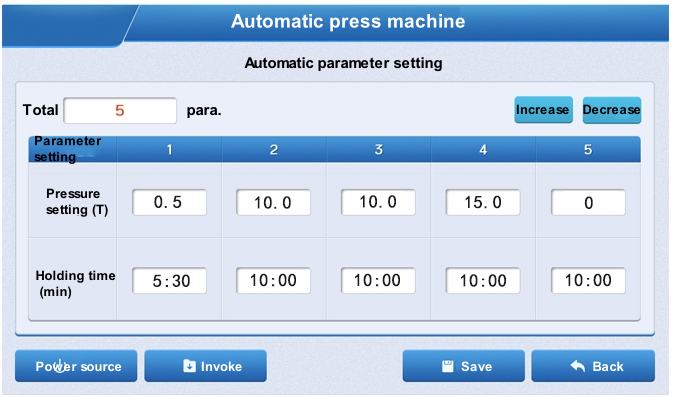

Setting interface

Multi-segment program Settings: Up to 5 segments of pressurized programs can be set.

Invoke button: Call the set parameters to the automatic operation interface for pressure.

Save button: Save the set parameters to the database for later invocation.

Back button: Returns to the Settings screen.

Operation procedure

Technical parameter

|

Instrument type |

PP-2S |

|

Pressure range |

0.01-2.00tons |

|

Pressurization process |

Common or connected multi-section pressure and can display pressure curves |

|

Holding time |

1 s to ∞ s |

|

Pressure conversion |

Program automatically converts mold pressure |

|

Liquid crystal display |

5 inch LCD screen |

|

Metal keying |

Silver-plated contact, service life > 100,000 times |

|

Equipment protection |

Steel plate protection with plexiglass doors |

|

Limit switch |

Automatic pressure relief when the cylinder reaches the limit height |

|

Remote control |

Optional computer for remote control and print reports |

|

Cylinder stroke |

30mm(T) |

|

Space size |

110x140mm(MXN) |

|

Overall dimension |

185X320X360mm(LxWXH) |

|

Equipment power supply |

240W(220V/110 can be customized) |

|

Equipment weight |

50Kg |

|

Powder press size diagram |

|

1. We supply machines with battery technology support.

2. We supply full set of lithium battery equipment for lab research, pilot scale research and production line.

|

|

|

|

|

|

|

|

|

|

|

Lab Mixer Machine |

|||

|

|

|

|

|

1 Standard exported package : Internal anticollision protection, external export wooden box package

2 Shipping by express, by air, by sea according to customer's requirements to suggest the most suitable shipping mode

3 Responsible for the damage during shipping process, change the damage part for free

4 Supply with suitable voltage input and power plug according to customer's country requirements.

5 Supply with CO, ECO, FORM A, FORM E and any other original certificate for import custom clearance and tax relief.

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com