- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

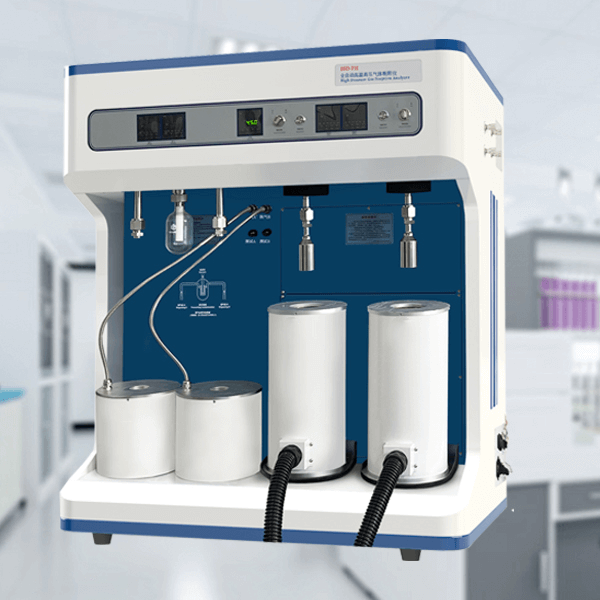

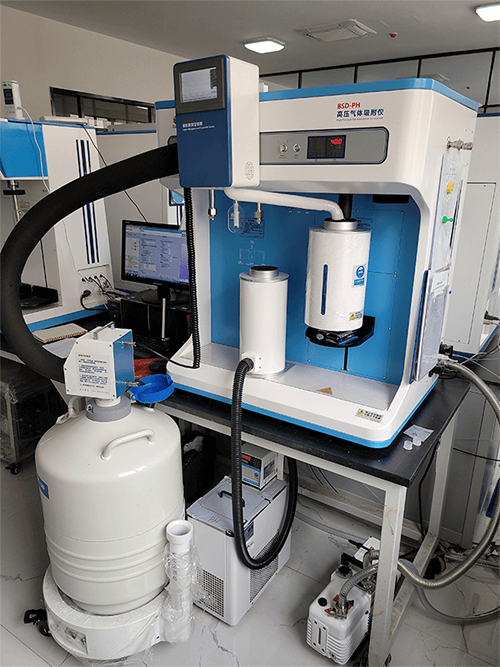

Static Capacity Method High Pressure Gas Adsorption Analyzer

Model Number:

TMAX-BSD-PHCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Static Capacity Method High Pressure Gas Adsorption Analyzer

Product description

The pressure range is 0-20MPa, the temperature range is -196°C~1100°C optional, and the number of analysis positions is optional 1/2/4.

Test principle

After the sample is placed in the sample tube, it will first be filled with an inert gas for calibration (such as helium) to calibrate the volume occupied by the sample and the remaining free space volume (dead volume) of the sample tube, and then a certain amount of adsorbate The gas is filled into the sample tube (injecting gas), and the software will automatically record the adsorption amount under the pressure value at this time when the adsorption is balanced. This operation is then automatically repeated until the desired maximum pressure value is reached. We plotted the pressure value corresponding to the adsorption amount to obtain the adsorption isotherm.

For some samples, the adsorption capacity at different temperatures is completely different. At this time, we can test the change of the gas adsorption capacity of the sample at different temperatures according to the actual needs of users.

For all these complex operations, Best BSD-PH series high temperature and high pressure gas adsorption instrument has been fully automated, and automatically performs complex data model processing to evaluate the high temperature and high pressure adsorption performance of the adsorption of samples.

Main function

a. Static capacity method high pressure gas adsorption;

b. High temperature and high pressure gas adsorption and desorption isotherm test;

c. PCT adsorption-desorption curve, adsorption constant;

d. Research on shale gas and coalbed methane reserve evaluation;

e. Hydrogen storage PCT, hydrogen absorption and desorption cycle test;

f. Research on adsorption properties of porous materials;

Optional features:

a. Atmospheric pressure desorption rate test;

b. Constant pressure adsorption rate test;

c. Programmed temperature desorption test;

d. High-pressure volumetric multi-component adsorption test;

Main parameter

a. Test accuracy: repeatability error is less than ±2%;

b. Pressure range: from high vacuum to the highest 690bar;

c. Temperature range: -196°C to 900°C;

d. Safety: The inside of the instrument has been tested by high pressure to ensure the airtightness of the instrument. At the same time, there is a built-in combustible gas alarm, and the gas alarm linkage system is optional;

e. Pressure accuracy: Imported high-precision pressure sensor, the accuracy is 0.01% FS, and the long-term use stability is 0.025% FS;

f. Constant temperature of the instrument (air bath): The internal temperature of the instrument is fully constant, and the branches, valves and air sources are in the same air bath environment. The constant temperature is 40.0°C, and the temperature control accuracy is ±0.1°C;

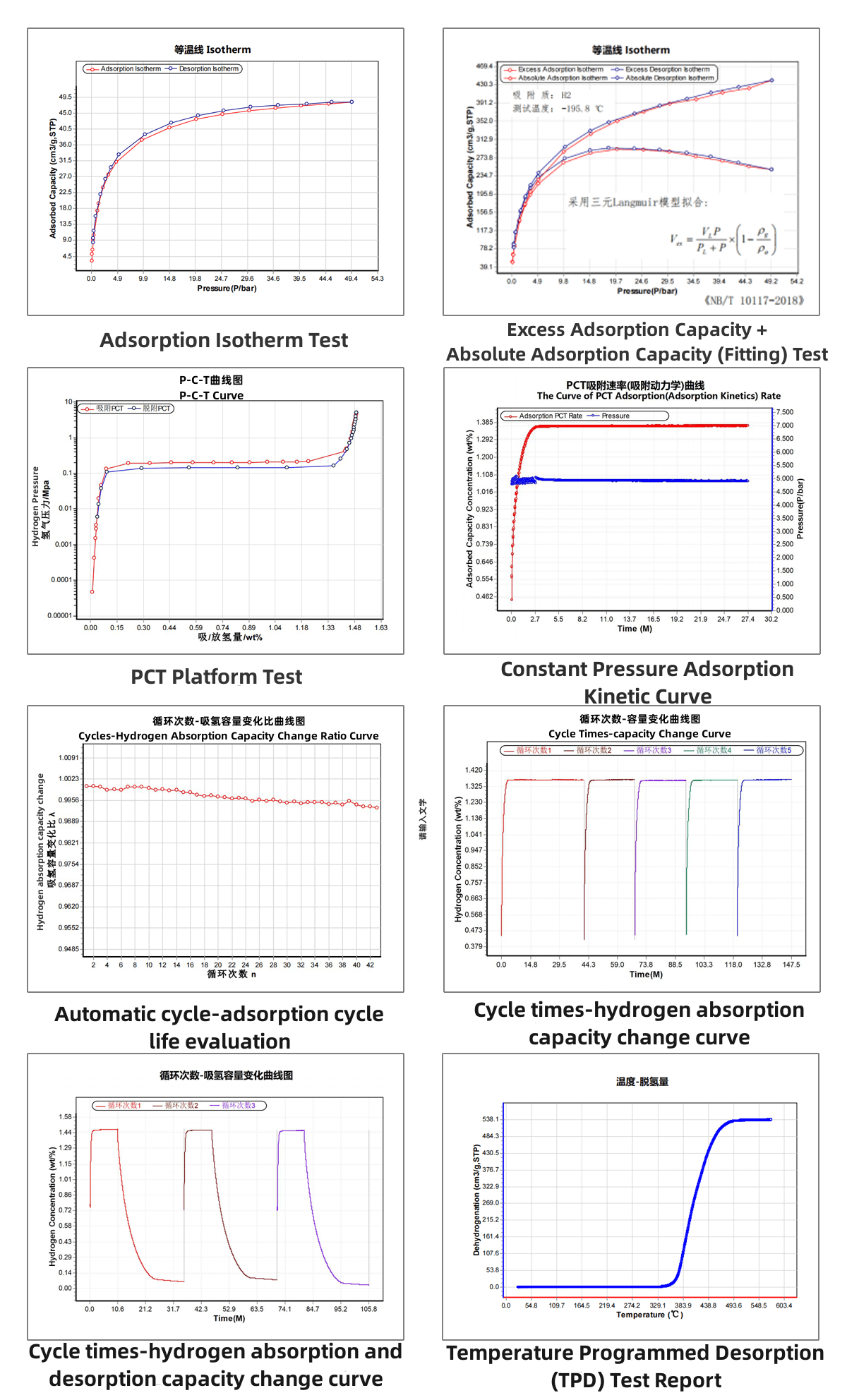

Data report

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com