- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Multi-component Competitive Adsorption Breakthrough Curve Analyzer

Model Number:

TMAX-BSD-MABCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Multi-component Competitive Adsorption Breakthrough Curve Analyzer

Product overview

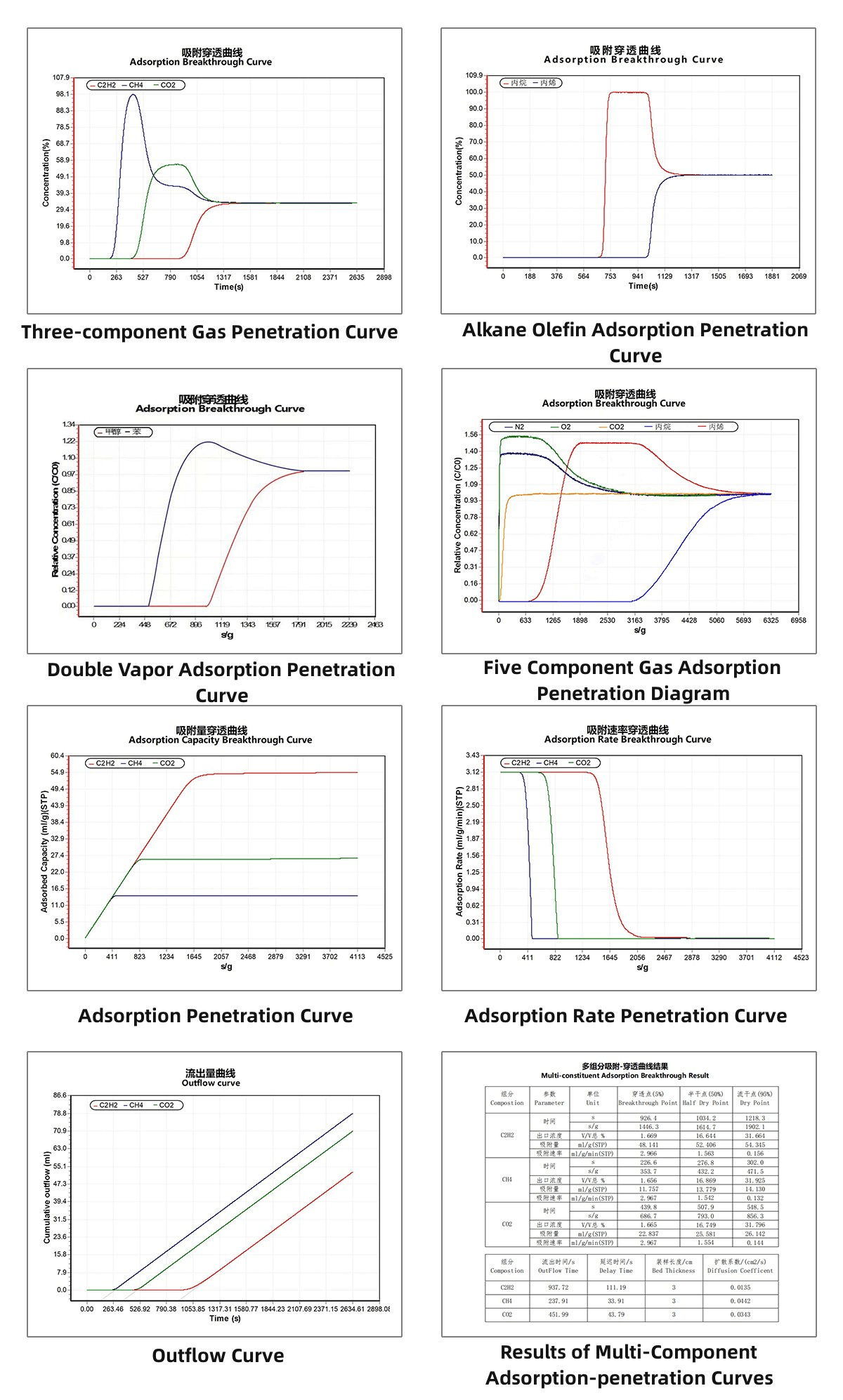

Research on gas/vapor separation

Study on multi-component competitive adsorption

Study on PSA swing adsorption

Research on air pollutant purification

In the study of the removal of VOCs, SO2, NH3 and other multi-component pollutants in the air, physical adsorption method has a wide range of application prospects and research value because of its advantages of high efficiency, low consumption, low concentration and no secondary pollution. And the penetrating curve analysis method is the classic method in this field because it is close to the actual application condition. Through this method, accurate information such as the amount of adsorbent, adsorption capacity, adsorption rate, purification effect, activation conditions, filter element life and so on can be given.

Different types of adsorbents for different fields of application, such as activated carbon has strong adsorption of VOCs gas, can be used for organic steam recovery and air purification; Molecular sieve, MOF and other materials have significant selective adsorption of specific gas, can be used for air separation, purification and other mixed gas separation fields.

Fixed bed reactor is widely used in industrial catalysis, high purity gas preparation, tail gas treatment and other fields. Physical adsorption on a fixed bed is the complete or selective absorption of multi-component adsorbent gas by adsorbent to achieve its industrial application. A complete understanding of the adsorption and desorption processes occurring on a fixed bed is the key to mixed gas adsorption and separation, industrial catalysis and other industrial applications. The penetration curve of a fixed bed reactor with a reasonable proportion of the separation process is the basis of the design and operation of the fixed bed adsorption process.

Test principle

The penetration column is equipped with granular adsorbent, piled into a bed with a certain height, the bed is stationary, the mixed gas through the adsorbent inlet into, adsorbent adsorption, and then outflow from the outlet, through the determination of the change of the concentration of each component of the export gas with time that is the penetration curve, To measure the penetration time of components in addition to carrier gas and the selective adsorption amount of each component of the gas mixture.

Major function

A. Use the adsorption penetration curve analyzer with its own thermal conductivity detector to determine the following different experimental conditions of the two-component adsorption penetration curve: different adsorbent, different temperature, different pressure, different bed thickness, different gas concentration, different penetration flow;

B. Connected chromatography or mass spectrometry -- Complete three or more components of the multi-component competitive adsorption, selective adsorption and displacement adsorption tests.

C. Realize the adsorption test of TVOC, SO2, NH3 and other pollution gases with ppm concentration of adsorbent, especially suitable for the evaluation of adsorption performance of trace pollution gases in indoor, car and other environment and the determination of adsorption parameters.

Application area

Gas separation study:

the reduction of reasonable proportion of separation process;

Provide technical support for adsorption tower design and application;

Research on selective adsorption (applied to adsorption separation technology);

Multi-component competitive adsorption study:

Study on adsorption kinetics of adsorbent;

Studies on coadsorption and displacement adsorption;

Dynamic multi-component adsorption and analytical experiment (explore the adsorbent regeneration ability);

Comparison of adsorption bond energy of different adsorbent and adsorbent (TPD);

Research on competitive adsorption;

Study on activation temperature of adsorbent (TPD);

Measurement of adsorption rate and adsorption capacity of adsorbent for mixed gas.

Variable pressure and temperature adsorption research:

Research on PSA and TSA;

Air pollutant purification research:

Test the limit volume of TVOC, SO2, NH3 and other pollution gases of the target concentration of adsorbent on the filter element in the air purifier, so as to obtain the adsorption efficiency and replacement frequency of the filter element;

Test the purification capacity and purification efficiency of the adsorbent in the tail gas treatment device;

Test report

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com