- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Three Axis Vibration Tester For Lab Scale Battery Safety Testing

Model Number:

TMAX-50SPSCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPlace of Origin:

ChinaPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Three Axis Vibration Tester For Lab Scale Battery Safety Testing

Product Introduction

The TMAX-50SPS three-axis series electromagnetic vibration table is an economical but highly cost-effective sinusoidal vibration testing equipment (functional cover fixed frequency vibration, linear sweep frequency vibration, logarithmic sweep frequency, doubling frequency, program, etc.), which simulates the vibration and its impact of electrical and electronic products during transportation (ships, airplanes, vehicles, spacecraft), storage, and use in the laboratory, and assesses its adaptability.

The TMAX-50SPS three-axis series electromagnetic vibration table is widely used in the design, research and development, and manufacturing processes of various industries such as automotive parts, instruments, and toys. It simulates the collision and vibration generated during transportation and use of products, and detects the actual working conditions and structural strength of products.

Product features

1. Realize X-axis, Y-axis, and Z-axis vibration on the same table, with program control, precise frequency, and no drift during long-term operation;

2. Stepless amplitude adjustment, with sweep and fixed frequency functions, suitable for testing requirements in different industries;

3. Embedded amplitude prediction program, four point synchronous excitation, uniform table vibration;

4. Add anti-interference circuits to solve the interference of strong electromagnetic fields on control circuits, and ensure that the tabletop is non-magnetic and static.

5. Made of composite industrial materials, precision machining, beautiful and elegant platform, user-friendly operation and control, using dedicated measurement and control modules to make the equipment work more stably.

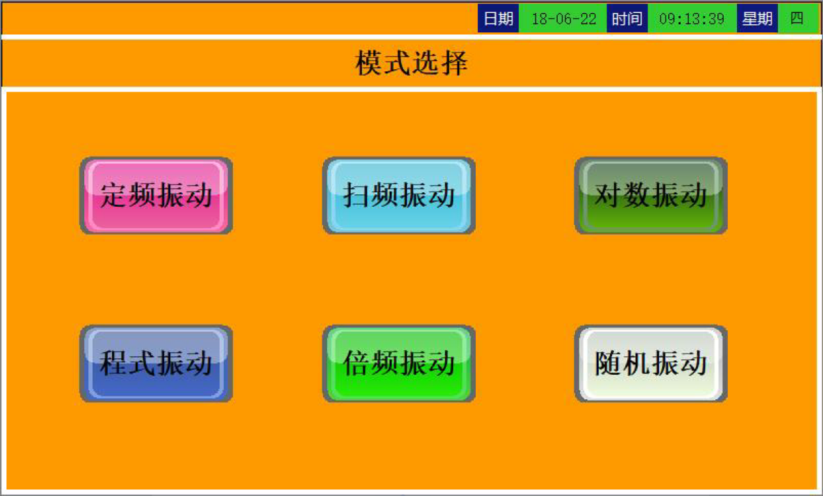

Software features

1. The TMAX-50SPS series vibration table software system is independently developed by CIMS+FCS, and has complete independent intellectual property rights. The software is free for lifelong updates and upgrades;

2. The system software is connected to the vibration table in real-time communication to ensure accurate testing parameters;

3. The software interface is intuitive and simple, with multiple testing mode partition settings and one click access;

4. The system software can be connected to a computer via a data cable to store, output, or edit test results;

5. The control system adopts a brand high sensitivity touch color LCD display, with direct touch options, intuitive and simple testing parameter settings, timely display of the current execution program, timely display of the current vibration frequency, and drawing frequency curve functions;

6. Using vibration sensing technology devices, external vibration acceleration sensors can be connected to provide real-time feedback on the testing process.

Technical parameter

|

Product model |

TMAX-50SPS (Three Axis) |

|

|

Frequency modulation range (Hz) |

1-600 (customizable for 1-5000) |

|

|

Product load (Kg) |

50 (customizable) |

|

|

Vibration direction |

Three axis (X+Y+Z) |

|

|

Worktable size (mm) |

(W) 500 x (D) 500 (customizable) |

|

|

Workbench body size (mm) |

(W)500×(D)500×(H)720 |

|

|

Control box size (mm) |

(W)500×(D)350×(H)1080 |

|

|

Frequency accuracy |

0.1 Hz |

|

|

Maximum acceleration |

20g |

|

|

control mode |

7-inch industrial touch screen |

|

|

Amplitude (mm) |

0-5 |

|

|

Excitation method |

Electromagnetic type |

|

|

Amplitude modulation method |

Electronic amplitude modulation |

|

|

Vibration waveform |

sine wave |

|

|

Time range |

0-9999H/M/S can be set arbitrarily |

|

|

Number of cycles |

0-9999 arbitrary settings |

|

|

Security protection |

Over temperature, phase loss, short circuit, overcurrent, overload |

|

|

Cooling method |

Air-cooled |

|

|

Test mode |

Fixed frequency test: Conduct a sinusoidal vibration test at a selected frequency (which can be a resonance frequency, a specific frequency, or a hazardous frequency) according to the specified value and meet the specified requirements for a specified period of time. |

|

|

Sweep frequency test: Within the specified frequency range, scan from low frequency to high frequency at a certain rate according to the specified value, and then from high frequency to low frequency as one sweep until the total number or time specified is reached. |

||

|

Double frequency test: The double frequency sweep should be continuous and its frequency should change exponentially over time. The sweep rate (the rate of change of controllable variable frequency over time during the sweep process, df/dt) should be one octave per minute. The test time (acceleration time) with a frequency range of f1 → f2 → f1 is calculated using the formula 6.644log10 (high/low frequency), and its scanning rate meets the requirement of 1 octave per minute. |

||

|

Logarithmic test: In logarithmic mode, the low-frequency scanning speed is slow, while the high-frequency scanning speed is fast. Logarithmic scanning is done in units of 1 minute, and the scanning rate is doubled within 1 minute. |

||

|

Random experiment: Random vibration is a type of non deterministic vibration. When an object undergoes random vibration, it is impossible for us to determine the instantaneous value of the motion parameters of a monitoring point on the object at a future time in advance. |

||

|

Program testing: Depending on the testing requirements, different testing frequencies and times can be set, and single or multiple groups can be used. |

||

|

Power supply voltage (V/Hz) |

220/50±5% |

|

|

Power consumption (KVA) |

1.5 |

|

|

Overall weight (Kg) |

245 |

|

Picture for reference

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com