- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

18650 Single Head Electrolyte Filling Machine

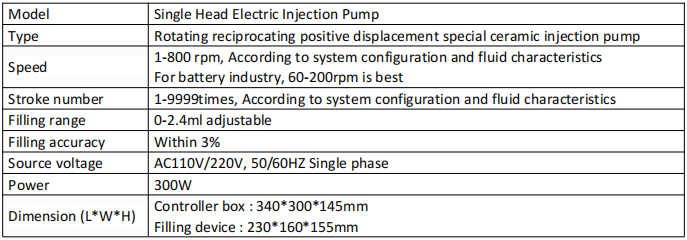

Model Number:

TMAX-JLB-10Type:

18650 Electrolyte Filling MachineMax. Loading Capacity:

0-2.5ml adjustableCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

18650 Single Head Electrolyte Filling Machine

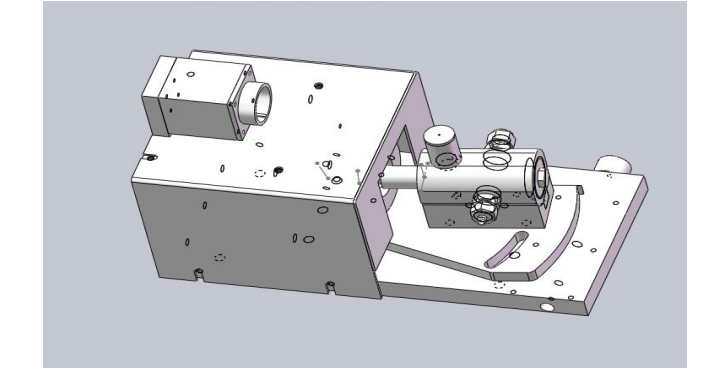

1. Working principle of injection pump

Rotary valve type liquid injection pump is a kind of power transmission device which converts electric energy into liquid kinetic energy. The ceramic plunger is driven by the stepper motor to rotate and reciprocate. The liquid is quantitatively pumped into the chamber through the liquid inlet, and then the liquid is pushed out of the chamber through the liquid outlet, and then injected into the equipment or product required by the user through the pipeline.

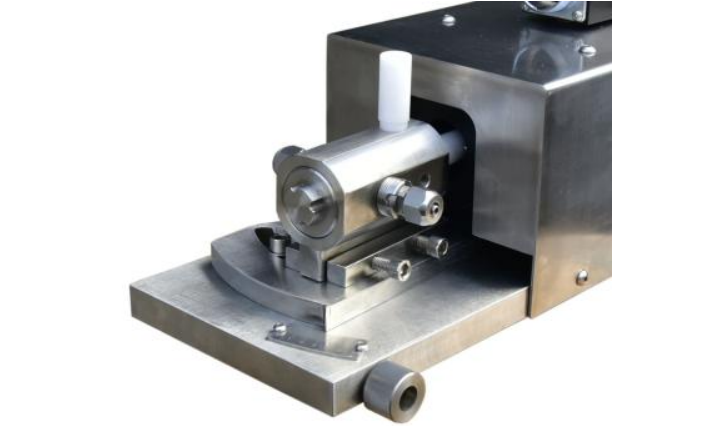

2. Characteristics of injection pump

2.1 high measurement accuracy: After repeated tests with water, oil, electrolyte and other fluids, the repeatability accuracy of our injection pump is within ± 0.25%.

2.2 the control function is perfect and the operation is simple

The touch screen has a man-machine interface with digital buttons, which is convenient for parameter setting and state monitoring; it has perfect application functions, such as single-step or continuous operation, interval times and stop functions of the injection pump, as well as emergency stop, positive and reverse rotation, fault detection and other equipment control operation functions. The perfect function can meet the needs of customers and improve the utilization efficiency of injection pump.

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com