- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

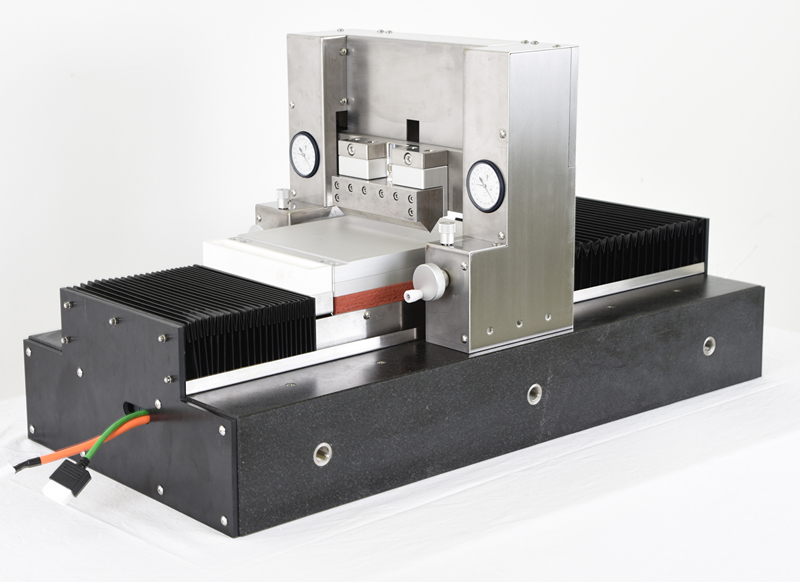

200MM Lab Desktop Manual Electrode Film Coating Slot Die Coater Coating Machine

Model Number:

TMAX-MSDCCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

200MM Lab Desktop Manual Electrode Film Coating Slot Die Coater Coating Machine

Manual feeding on the coating platform (fixed by adsorption) - feeding system feeding die head - coating platform forward positioning - die head down positioning - start coating - coating system coating according to the set parameters - coating completion - feeding stop - manual product removal - completion.

Equipment composition

1) Substrate positioning platform

2) Feeding system

3) Slit coating unit

4) Platform adsorption

5) Coating die position control, platform moving unit

Specifications

|

1. Basic parameters of base material |

|

|

Type |

Glass, silicon, flexible/soft sheet |

|

Thickness |

0.05~3mm |

|

Base material length and width |

Max.200mm W X 300mm L |

|

2. Coating parameters |

|

|

Coating thickness (dry) |

0.05-15um(for reference, actual depends on solution characteristics) |

|

Solid content |

10-70 |

|

Viscosity |

1-10000cp |

|

3. Basic parameters of the machine |

|

|

Coating method |

Slot die coating |

|

Effective width of coating |

Max. 200 mm; |

|

Coating platform speed |

0.06m-3m/min |

|

Coating platform |

250mm W*350mm L,Platform flatness: ± 0.05mm |

|

Power Supply |

220 V, 50 Hz |

|

Total power |

Max. 2 KW (with heating on) |

|

Air source |

0.6 MPa |

|

Machine dimensions |

Max. 1200mm L X 450mm W X 450 mm H(for reference, subject to final dimensions) |

Coating unit

|

Coating method |

Slot die coating |

|

Distance between die head and platform |

Fine adjustable range: 0.01-10mm Unit adjustment accuracy: 0.002mm Coarse adjustable range: 0-20mm With cleaning tank |

|

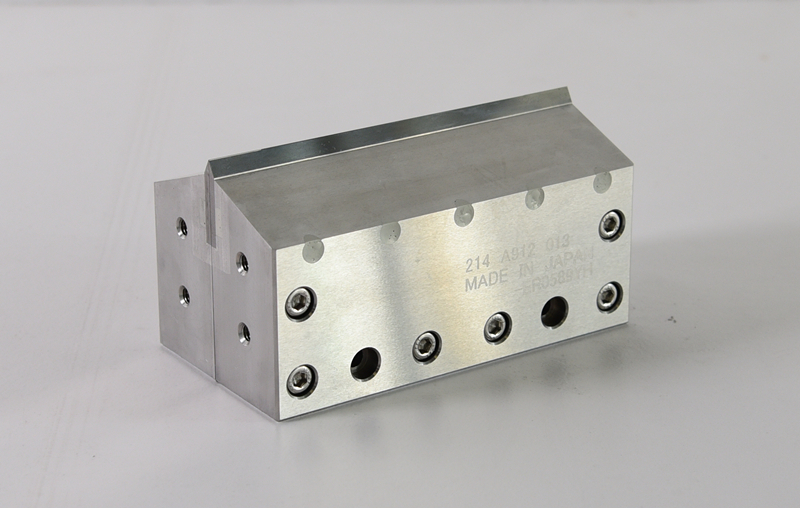

Die head (effective width 200 mm) |

included |

|

Platform driven |

Servo motor + ball screw + servo controller |

Platform adsorption/baking unit

|

Heating platform |

Al alloy, surface oxidation, accuracy 20μm |

|

Heater |

Electric heating components |

|

Heating temperature |

Temperature: RT-160 ℃, temperature control accuracy ≤± 3℃ (effective area: 200mmX300mm) |

|

Platform adsorption |

Aperture: 0.5mm , hole spacing: 25mm |

1. We supply machines with battery technology support.

2. We supply full set of lithium battery equipment for lab research, pilot scale research and production line.

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com