- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

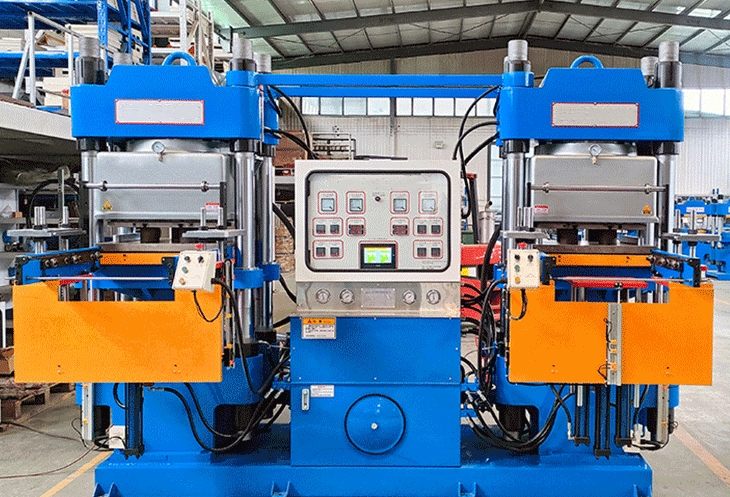

200T Double Layer Automatic Rubber Vulcanizing Moulding Press Machine

Model Number:

TMAX-XLHSCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

200T Double Layer Automatic Rubber Vulcanizing Moulding Press Machine

Introduction

The semi-automatic double-layer vulcanizing machine adopts imported hydraulic components and electrical components. Under the action of the working fluid pressure, the plunger of the vulcanizing machine rises and descends (i.e., the hot plate opens). Relying on the self-weight of the hot plate, the platform and the plunger, the working fluid flows back to the oil storage tank, achieving the purpose of descending (i.e., opening).

The working fluid of the vulcanizing machine enters the cylinder through the control valve. By turning the control handle to different positions, the plunger of the flat vulcanizing machine can rise or fall.

Features

This series of models is equipped with automatic control devices for pressure, time and temperature. It can achieve mold closing and pressure increase, timed working cycles, and automatic pressure replenishment to ensure the quality of pressed products. The structure is compact, the appearance is beautiful, and the operation is convenient.

This product is a new generation of flat vulcanizing machine. It adopts a working mode where a fast cylinder drives the plunger to automatically draw in oil. Compared with the previous flat vulcanizing machines driven by high and low pressure oil pumps, it saves energy by more than 30%. And significantly enhance work efficiency. It is the preferred product for energy conservation and environmental protection.

It adopts a 7.1-inch large touch screen for operation and can preset 6 sets of mold vulcanization parameters. It is equipped with a parameter password protection function, and workers cannot change the equipment parameters at will

It has an automatic locking function during vulcanization. In the vulcanization state, workers cannot open the mold at will unless a password is entered to unlock it, ensuring the vulcanization time of the product.

It has the function of output memory. It can store and remember the output within a week, making the production capacity clear at a glance.

It has a timed heating function and can be set to start heating at any time within 24 hours of a day.

Application

This product is widely used in the following industries:

The semi-automatic double-layer vulcanizing machine series hydraulic press is suitable for the rolling, embossing, forming of thin metal sheets and the shallow drawing process of plastic materials. Such as the pressing of watch cases, case backs, watch straps, various gold and silver jewelry, badges, commemorative coins, glasses, and the shells of lighting fixtures, etc.

The main equipment used for pressing various rubber model products and non-model products can also be used for pressing various thermosetting plastics and foamed rubber and plastic products.

Technical parameters

|

Nominal force (T) |

200 |

|

|

Rated working pressure (MPa) |

25 |

|

|

Spacing (mm) |

150 |

|

|

Stroke (mm) |

300 |

|

|

Number of oil cylinders |

Main cylinder1, Auxiliary cylinder2 |

|

|

Inner diameter of the oil cylinder (mm) |

320 |

|

|

Number of working levels |

2 |

|

|

Number of heating plates |

3 |

|

|

Heating method |

electric |

|

|

Heating power (KW) |

14.4 |

|

|

Control mode |

automatic |

|

|

Effective area of the heating plate (mm) |

Left & right |

600 |

|

Front & back |

600 |

|

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com