- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

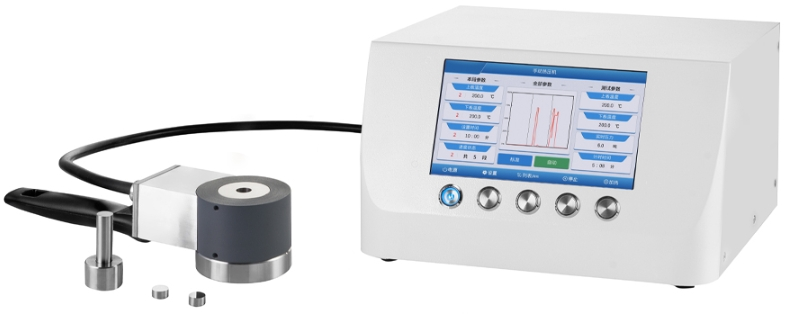

300C High Temperature Alloy Tool Steel Cylindrical Electric Heating Mold

Model Number:

TMAX-PCH-MDimension(L*W*H):

Max. Tablet Diameter(mm): 100mmNet Weight:

1kgCompliance:

CE certificatePayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

300C High Temperature Alloy Tool Steel Cylindrical Electric Heating Mold

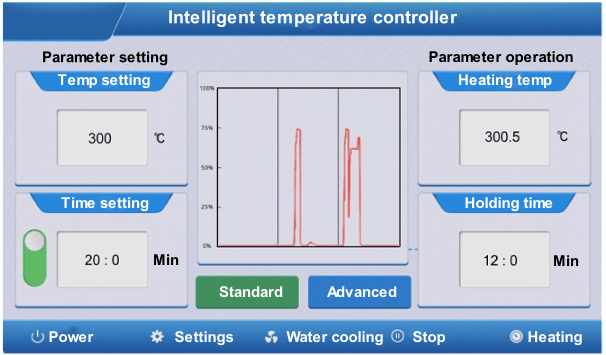

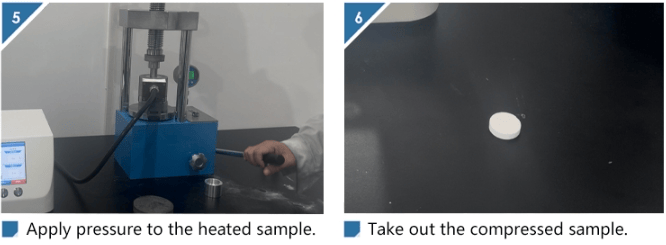

Operation interface (Standard mode)

Standard interface: The heating temperature and constant temperature time of the mold can be set separately on this interface.

Water-cooling button: The power supply of the water-cooling machine is connected to the thermostat, which can control the on and off of the water-cooling machine.

Heating button: Click this button and the mold will start heating.

Stop button: Click this button and the mold will stop heating.

Timing switch: Used to turn the timing function on and off.

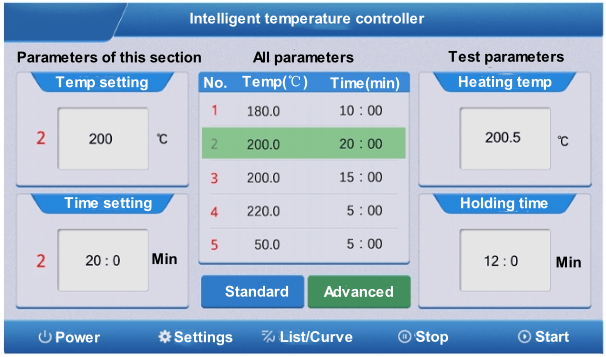

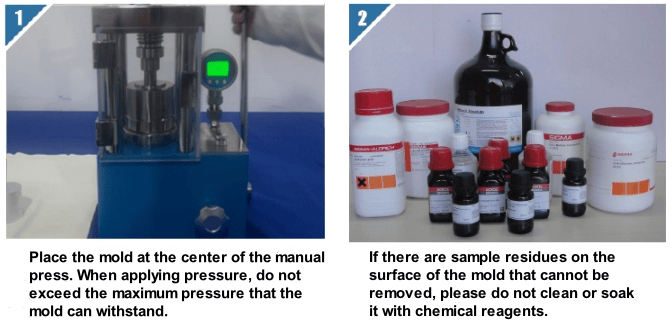

Operation interface (Advanced mode)

Start button: In the advanced mode, by clicking the start button, the hydraulic press can be heated up according to the multi-stage heating program.

Stop button: During the heating process, clicking the stop button can stop the heating.

List curve: Current display status. The list and curve graph can be switched.

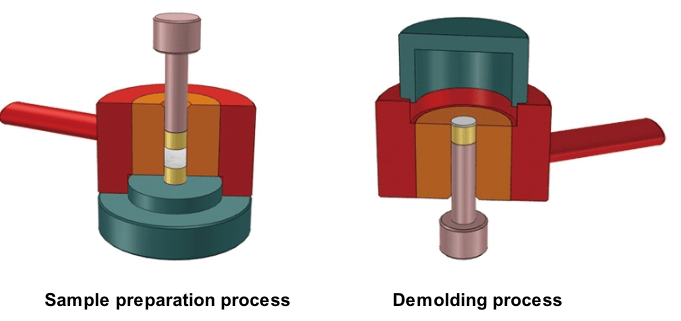

Schematic diagram of mold operation

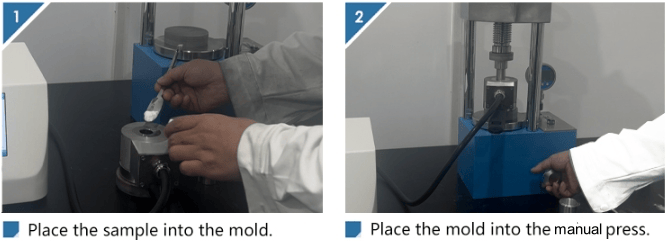

Operation steps

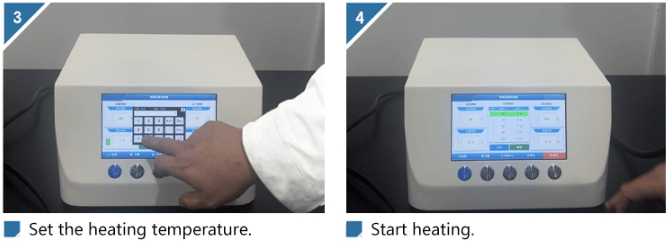

Mold usage and maintenance

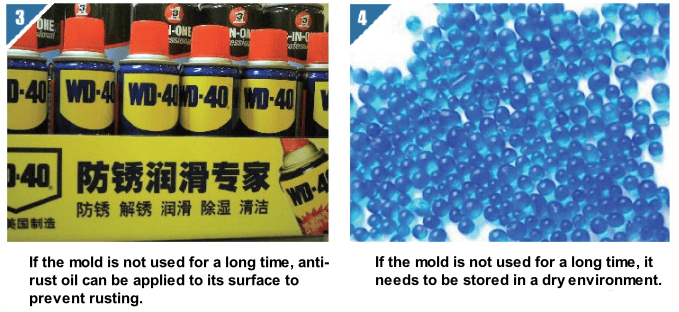

Each time the mold is used, the surface of the mold should be wiped clean with lint-free paper first to prevent the anti-rust oil on the mold from affecting the test results of the sample. When applying pressure, it is necessary to pay attention not to exceed the maximum pressure that the mold can withstand. After using the mold, the samples on the mold should be cleaned in time to prevent corrosion of the mold. When the mold is not used for a long time, anti-rust oil should be applied to the mold and it should be stored in a dry environment.

Technical parameters

|

Instrument model |

PCH-M |

|

Pressed sample shape |

|

|

Heating temperature |

Room temperature - 300.0℃ |

|

Mold material |

Alloy tool steel :440C |

|

Indenter hardness |

HRC60-HRC62 |

|

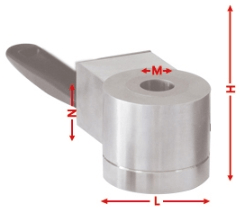

Sample size |

φ10, φ13, φ15, φ20, φ30, φ40mm(M) |

|

Cavity depth |

40mm(N) |

|

External dimensions |

φ78x138mm, φ90x138mm(LXH |

|

Power supply power |

300W(220V/110V, customizable) |

|

Mold weight |

About 9 kg |

|

Schematic diagram of dimensions |

|

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com