- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

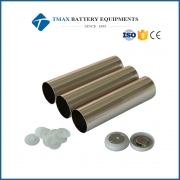

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

TMAX provides professional cylindrical cell machine line, mainly include the electrode mixer for slurry, electrode film coating machine, electrode calendaring machine, cylindrical cell sealing machine for cylindrical cell crimping. All the mahchines suitable for all kinds of cylindrical cells, such as 18650, 21700, 26650, 32650, 4680 etc

|

Cylindrical Cell Machine |

Cylindrical Cell Lab Line |

50 Pcs/day |

|

Cylindrical Cell Production Line |

100 MWH/year 1 GWH/year |

|

|

Cylindrical Cell Pack Assembly Line |

500 Pcs/day |

|

|

Battery Size: 18650,21700,26650,32650,32700 etc Battery Production Line: Supply"Turn key"Project service. Material System: LFP, NCM, NCA, LCO, Sodium ion Main Process: Winding process Production Capacity: Accept customization Technology: Battery Technology consulting, Guidance,Training, Transfer, etc. |

||

-

Automatic CNC Battery Spot Welding Machine Welder

Automatic CNC Battery Spot Welding Machine Welder

-

18650 Single Point Pneumatic Welder

18650 Single Point Pneumatic Welder

-

Laboratory Water Purifier Deionized Water Machine

Laboratory Water Purifier Deionized Water Machine

-

Semi-Automatic Adjustable Electrode Slitting Machine For Coated Electrodes Plates

Semi-Automatic Adjustable Electrode Slitting Machine For Coated Electrodes Plates

-

Automatic Double-sided 18650 Spot Welding Machine

Automatic Double-sided 18650 Spot Welding Machine

-

10-300mm Width Roller Coater for Electrode Coating

10-300mm Width Roller Coater for Electrode Coating

-

18650 Cell Case With Anti-Explosive Cap

18650 Cell Case With Anti-Explosive Cap

-

18650 Quartz Split Type Test Cell For Research

18650 Quartz Split Type Test Cell For Research

-

60L Air Compressor For Compressed Air Source Supply

60L Air Compressor For Compressed Air Source Supply

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com