- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

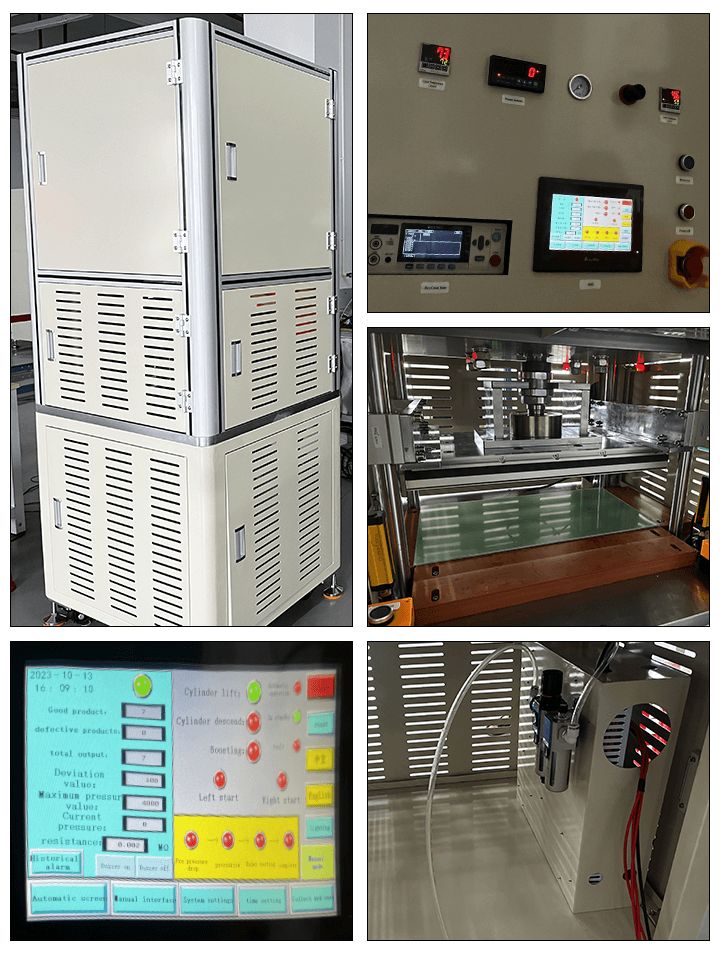

Large Heat Press Machine For Polymer Battery Core Hot Press

Model Number:

TMAX-A-017Compliance:

CE CertifiedWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Large Heat Press Machine For Polymer Battery Core Hot Press

Functions

● Apply to lithium battery auto hot-pressing plastic soft package, cold press finalize the sharp.

Features

● Separable structure gas rose axis, forklift load/unload material strap roll material;● Hot-pressing temperature: room temperature up to -120° C is adjustable, can be set up compensation, heating at a single point in the template control accuracy ± - 3 ° C;

● Presetting cold, hot pressing temperature and the holding time, have abnormal temperature alarm function;

● Automatic control is realized by using PLC, touch screen man-machine dialogue, convenient operation and setting;

● Top and bottom template parallelism: ±- 0.02 mm, three pieces non-carbon paper are available down out evenly when in the 1 T settle pressure, temperature;

● Hot pressing plate for copper, greatly improving the heat transfer rate, improve the uniformity of the different location of the hot platen temperature;

● Mylar circulating feeding, front-rear stability, reduce the time of manual handling;

● Mylar volume gas rose axis loading, winding speed is adjustable, gas rose axis can be separated, convenient load Mylar.

Technical Parameters(for reference):

|

ITEM |

HB-LRY300 |

HB-LRY350 |

|

Measures |

(L*W*H)2300*800*1800mm |

(L*W*H)2300*800*1800mm |

|

Weight |

About 850Kg |

About 850Kg |

|

Power |

AC220V 50HZ, 7.5KW |

AC220V 50HZ, 7.5KW |

|

Air source |

≧0.6Mpa,20L/Min |

≧0.6Mpa,20L/Min |

|

Applicable range |

L≤300mm w≤300mm |

L≤350mm w≤350mm |

|

Capacity |

Depend on cold & hot press time |

Depend on cold & hot press time |

|

Action |

≧99% |

≧99% |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com