- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

Pouch Cell Case Forming Machine with Optional Die

Model Number:

TMAX-SCK200Type:

Pouch Cell Forming MachineDimension(L*W*H):

Size is 160mm (L) x 120mm (W) x 6mm (H) It can beNet Weight:

160kgCompliance:

CE certificateWarranty:

Two Year Limited Warranty With Lifetime SupportPayment:

T/T, Credit Card, Paypal, LC, Western UnionDelivery Time:

3 Days

Pouch Cell Case Forming Machine with Optional Die

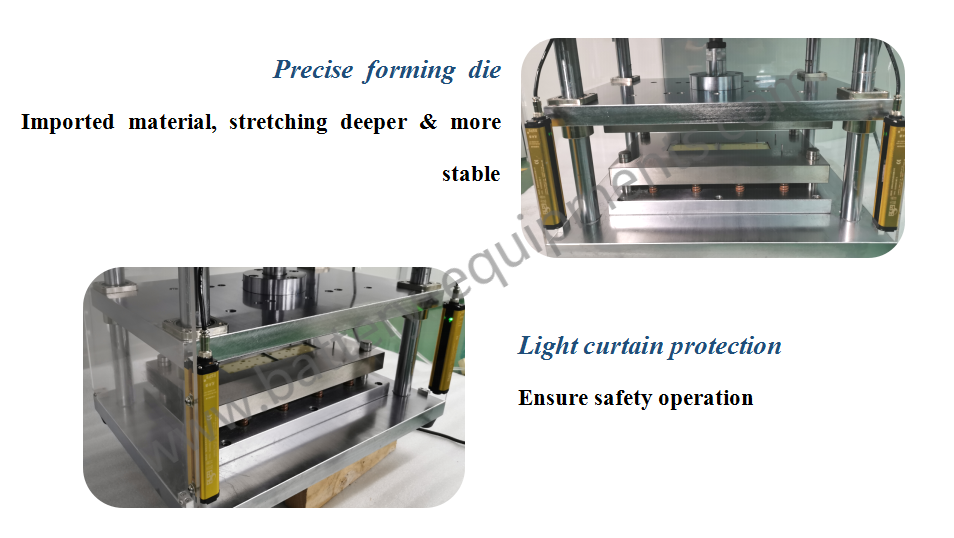

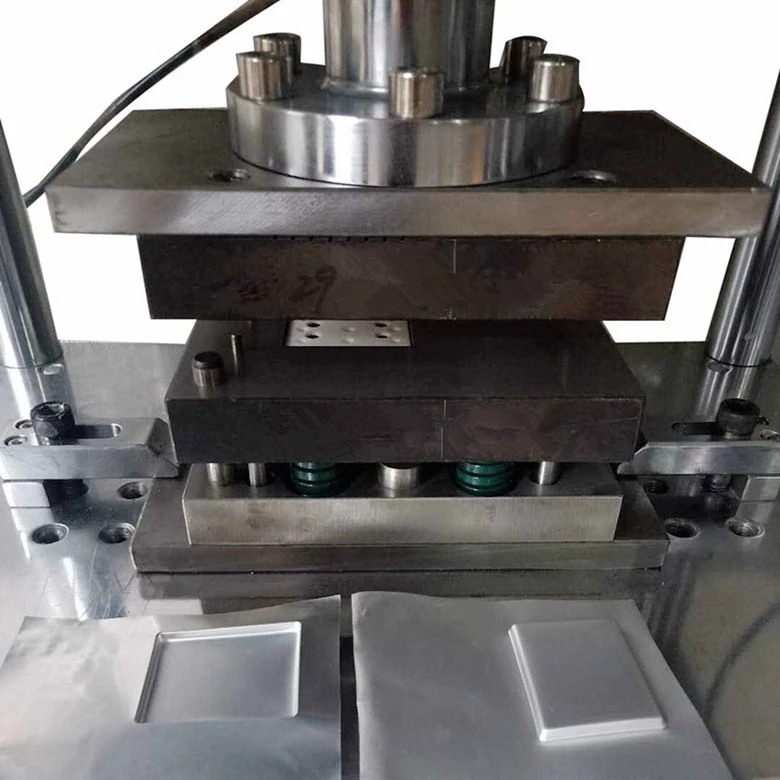

TMAX-SCK200 is a CE Certified cup forming machine used in the production line of making pouch cell batteries with optional size range. It is used to prepare polymer cases made of Aluminum Laminated Films. To ensure continuity and compatibility for customer's research, adjustable depth (spacers is included in standard package) to directly match the electrodes cut by electrode cutting machine.

SPECIFICATIONS:

|

Model |

Lab Polymer Battery Pouch Forming Machine TMAX-SCK200 |

|

Source voltage |

AC 220V/110V, 50/60HZ |

|

Power |

100W |

|

Warranty |

Two years limited warranty with lifetime support |

|

Advantages |

1 Structure of guide pin, slide up and down smoothly with high precision 2 Change mould, adjust tensile depth simply, quickly 3 Use screen and casing protection, guarantee safety 4 High strength of chrome steel and aluminum alloy, surface roasts the paint processing through environmental protection electroplating |

|

Suitable aluminum film thickness |

0.1-0.2mm |

|

Suitable mold size |

Customized as customer's request, with punching depth ≤24mm |

|

Max. Cup Depth |

Single pit punching depth ≤24mm |

|

Output |

200-400EA/H |

|

Output pressure |

5T |

|

Air source |

0.5-0.7MPa |

|

Mold materials |

SS136 Die steel |

|

Dimension (L*W*H) |

460*320*925mm |

|

Weight |

About 130kg |

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com