- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

blog

Pouch Cell pilot Machine

- 2025-04-15

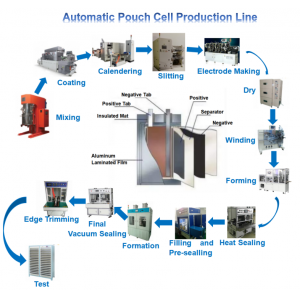

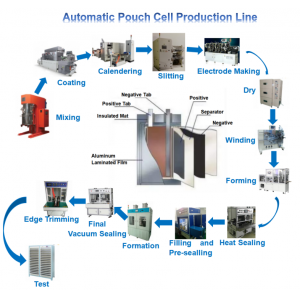

Pouch Cell Pilot Machine: Design, Functionality, and Applications

A Pouch Cell Pilot Machine is a semi-automated or fully automated system designed to facilitate the small-scale production of pouch cells (lithium-ion batteries packaged in flexible aluminum-plastic laminated pouches). These machines are used in pilot plants to bridge the gap between laboratory-scale research and full-scale commercial production. They allow manufacturers to test, optimize, and validate manufacturing processes before scaling up to mass production.

Below is a comprehensive overview of pouch cell pilot machines, including their design, functionality, applications, advantages, challenges, and market trends.

---

●1. What Is a Pouch Cell Pilot Machine?

A pouch cell pilot machine is an advanced tool that integrates multiple stages of pouch cell fabrication into a single system. It is designed to produce small batches of pouch cells with high precision and repeatability. The machine operates in a controlled environment, ensuring consistent quality and performance of the cells.

Key features of pouch cell pilot machines:

- Modular design for flexibility.

- Integration of key processes such as stacking, sealing, and testing.

- Scalability to accommodate different cell sizes and chemistries.

---

●2. Key Components of a Pouch Cell Pilot Machine

A typical pouch cell pilot machine consists of the following components:

A. Material Preparation

- Slurry Mixing: Equipment for mixing active materials, binders, and solvents.

- Coating: Machines for applying slurries onto current collectors (aluminum or copper foils).

- Drying: Ovens or dry rooms to remove solvents from coated electrodes.

B. Electrode Processing

- Calendaring: Roll presses to compact electrodes and control thickness.

- Slitting: Cutting electrodes into strips of specific dimensions.

C. Cell Assembly

- Stacking: Automated systems for stacking cathode, separator, and anode layers into a flat structure.

- Lamination: Equipment for inserting the stacked electrodes into pouches made of aluminum-plastic laminate.

- Sealing: Hot pressing or impulse welding machines to seal three sides of the pouch, leaving one side open for electrolyte injection.

D. Electrolyte Injection

- Precision equipment for injecting electrolyte into the pouch through the open side.

E. Final Sealing

- Equipment for sealing the final open side after electrolyte injection.

F. Formation and Testing

- Formation: Controlled charging/discharging cycles to activate the battery.

- Testing: Equipment to evaluate capacity, internal resistance, cycle life, and safety.

G. Environmental Control

- Dry Rooms: Low-humidity environments (<1% RH) to prevent moisture contamination during electrode processing and cell assembly.

---

●3. Operation of a Pouch Cell Pilot Machine

The operation of a pouch cell pilot machine involves several steps:

1. Material Preparation:

- Mix active materials, binders, and solvents to create slurries.

- Coat the slurries onto current collectors using slot-die or blade coating techniques.

2. Electrode Fabrication:

- Dry the coated electrodes in controlled ovens.

- Calender the dried electrodes to achieve desired thickness and density.

- Slit the electrodes into strips of precise dimensions.

3. Cell Assembly:

- Stack the cathode, separator, and anode layers into a flat structure.

- Insert the stacked electrodes into a pouch made of aluminum-plastic laminate.

- Seal three sides of the pouch, leaving one side open for electrolyte injection.

4. Electrolyte Injection:

- Inject electrolyte into the pouch through the open side.

5. Final Sealing:

- Seal the final open side after electrolyte injection.

6. Formation and Testing:

- Perform formation cycles to activate the battery.

- Conduct various tests (e.g., charge/discharge, thermal cycling, short-circuit testing) to evaluate performance and safety.

Pouch Cell Production Line

●4. Applications of Pouch Cell Pilot Machines

A. Process Validation

- Validate manufacturing processes before scaling up to full production.

- Identify bottlenecks or issues in assembly, sealing, or electrolyte injection.

B. Prototype Production

- Produce small batches of pouch cells for testing in electric vehicles (EVs), consumer electronics, or energy storage systems.

C. Quality Assurance

- Ensure consistent quality and performance across batches.

- Identify defects or inconsistencies early in the development process.

D. New Chemistry Development

- Test and optimize new battery chemistries (e.g., solid-state electrolytes, silicon anodes, high-nickel cathodes).

---

●5. Advantages of Pouch Cell Pilot Machines

| Advantage | Description |

|----------------------------------|---------------------------------------------------------------------------------|

| Precision | Enables accurate control over electrode dimensions, stacking, and sealing. |

| Scalability | Provides a platform to scale up from lab-scale experiments to full production. |

| Flexibility | Supports rapid iteration and testing of new materials and designs. |

| Cost-Effectiveness | Reduces risks and costs associated with large-scale production. |

| Data Collection | Generates valuable data on cell performance, reliability, and safety. |

---

●6. Challenges in Using Pouch Cell Pilot Machines

A. Equipment Complexity

- Advanced machinery requires skilled operators and regular maintenance.

B. Environmental Control

- Maintaining low-humidity conditions in dry rooms is challenging and costly.

C. Sealing Integrity

- Achieving reliable and leak-free sealing of pouches is critical but difficult.

D. Material Handling

- Ensuring uniform mixing, coating, and drying of electrode materials is essential but challenging.

E. Scalability

- Transferring processes from pilot scale to full production may reveal unforeseen challenges.

---

●7. Market Trends and Future Outlook

A. Increasing Demand for Lithium-Ion Batteries

- Growth in electric vehicles (EVs), renewable energy storage, and portable electronics drives demand for pouch cells.

B. Emerging Technologies

- Solid-state batteries, silicon anodes, and other next-generation technologies are being tested in pouch cell pilot machines.

C. Automation and Digitalization

- Adoption of Industry 4.0 technologies (e.g., IoT, AI, robotics) improves efficiency and reduces costs in pouch cell fabrication.

D. Sustainability

- Focus on recycling and sustainable manufacturing processes is gaining traction.

---

●8. Conclusion

Pouch cell pilot machines are essential tools for advancing battery technology and ensuring successful commercialization. They enable manufacturers to develop, test, and optimize pouch cells in a controlled and efficient manner. While challenges exist, ongoing innovations in equipment, processes, and materials continue to enhance the capabilities of these machines.

If you're planning to set up or operate a pouch cell pilot machine, carefully consider factors such as equipment specifications, environmental control, and scalability. For further details or assistance, feel free to ask!

A Pouch Cell Pilot Machine is a semi-automated or fully automated system designed to facilitate the small-scale production of pouch cells (lithium-ion batteries packaged in flexible aluminum-plastic laminated pouches). These machines are used in pilot plants to bridge the gap between laboratory-scale research and full-scale commercial production. They allow manufacturers to test, optimize, and validate manufacturing processes before scaling up to mass production.

Below is a comprehensive overview of pouch cell pilot machines, including their design, functionality, applications, advantages, challenges, and market trends.

---

●1. What Is a Pouch Cell Pilot Machine?

A pouch cell pilot machine is an advanced tool that integrates multiple stages of pouch cell fabrication into a single system. It is designed to produce small batches of pouch cells with high precision and repeatability. The machine operates in a controlled environment, ensuring consistent quality and performance of the cells.

Key features of pouch cell pilot machines:

- Modular design for flexibility.

- Integration of key processes such as stacking, sealing, and testing.

- Scalability to accommodate different cell sizes and chemistries.

---

●2. Key Components of a Pouch Cell Pilot Machine

A typical pouch cell pilot machine consists of the following components:

A. Material Preparation

- Slurry Mixing: Equipment for mixing active materials, binders, and solvents.

- Coating: Machines for applying slurries onto current collectors (aluminum or copper foils).

- Drying: Ovens or dry rooms to remove solvents from coated electrodes.

B. Electrode Processing

- Calendaring: Roll presses to compact electrodes and control thickness.

- Slitting: Cutting electrodes into strips of specific dimensions.

C. Cell Assembly

- Stacking: Automated systems for stacking cathode, separator, and anode layers into a flat structure.

- Lamination: Equipment for inserting the stacked electrodes into pouches made of aluminum-plastic laminate.

- Sealing: Hot pressing or impulse welding machines to seal three sides of the pouch, leaving one side open for electrolyte injection.

D. Electrolyte Injection

- Precision equipment for injecting electrolyte into the pouch through the open side.

E. Final Sealing

- Equipment for sealing the final open side after electrolyte injection.

F. Formation and Testing

- Formation: Controlled charging/discharging cycles to activate the battery.

- Testing: Equipment to evaluate capacity, internal resistance, cycle life, and safety.

G. Environmental Control

- Dry Rooms: Low-humidity environments (<1% RH) to prevent moisture contamination during electrode processing and cell assembly.

---

●3. Operation of a Pouch Cell Pilot Machine

The operation of a pouch cell pilot machine involves several steps:

1. Material Preparation:

- Mix active materials, binders, and solvents to create slurries.

- Coat the slurries onto current collectors using slot-die or blade coating techniques.

2. Electrode Fabrication:

- Dry the coated electrodes in controlled ovens.

- Calender the dried electrodes to achieve desired thickness and density.

- Slit the electrodes into strips of precise dimensions.

3. Cell Assembly:

- Stack the cathode, separator, and anode layers into a flat structure.

- Insert the stacked electrodes into a pouch made of aluminum-plastic laminate.

- Seal three sides of the pouch, leaving one side open for electrolyte injection.

4. Electrolyte Injection:

- Inject electrolyte into the pouch through the open side.

5. Final Sealing:

- Seal the final open side after electrolyte injection.

6. Formation and Testing:

- Perform formation cycles to activate the battery.

- Conduct various tests (e.g., charge/discharge, thermal cycling, short-circuit testing) to evaluate performance and safety.

Pouch Cell Production Line

●4. Applications of Pouch Cell Pilot Machines

A. Process Validation

- Validate manufacturing processes before scaling up to full production.

- Identify bottlenecks or issues in assembly, sealing, or electrolyte injection.

B. Prototype Production

- Produce small batches of pouch cells for testing in electric vehicles (EVs), consumer electronics, or energy storage systems.

C. Quality Assurance

- Ensure consistent quality and performance across batches.

- Identify defects or inconsistencies early in the development process.

D. New Chemistry Development

- Test and optimize new battery chemistries (e.g., solid-state electrolytes, silicon anodes, high-nickel cathodes).

---

●5. Advantages of Pouch Cell Pilot Machines

| Advantage | Description |

|----------------------------------|---------------------------------------------------------------------------------|

| Precision | Enables accurate control over electrode dimensions, stacking, and sealing. |

| Scalability | Provides a platform to scale up from lab-scale experiments to full production. |

| Flexibility | Supports rapid iteration and testing of new materials and designs. |

| Cost-Effectiveness | Reduces risks and costs associated with large-scale production. |

| Data Collection | Generates valuable data on cell performance, reliability, and safety. |

---

●6. Challenges in Using Pouch Cell Pilot Machines

A. Equipment Complexity

- Advanced machinery requires skilled operators and regular maintenance.

B. Environmental Control

- Maintaining low-humidity conditions in dry rooms is challenging and costly.

C. Sealing Integrity

- Achieving reliable and leak-free sealing of pouches is critical but difficult.

D. Material Handling

- Ensuring uniform mixing, coating, and drying of electrode materials is essential but challenging.

E. Scalability

- Transferring processes from pilot scale to full production may reveal unforeseen challenges.

---

●7. Market Trends and Future Outlook

A. Increasing Demand for Lithium-Ion Batteries

- Growth in electric vehicles (EVs), renewable energy storage, and portable electronics drives demand for pouch cells.

B. Emerging Technologies

- Solid-state batteries, silicon anodes, and other next-generation technologies are being tested in pouch cell pilot machines.

C. Automation and Digitalization

- Adoption of Industry 4.0 technologies (e.g., IoT, AI, robotics) improves efficiency and reduces costs in pouch cell fabrication.

D. Sustainability

- Focus on recycling and sustainable manufacturing processes is gaining traction.

---

●8. Conclusion

Pouch cell pilot machines are essential tools for advancing battery technology and ensuring successful commercialization. They enable manufacturers to develop, test, and optimize pouch cells in a controlled and efficient manner. While challenges exist, ongoing innovations in equipment, processes, and materials continue to enhance the capabilities of these machines.

If you're planning to set up or operate a pouch cell pilot machine, carefully consider factors such as equipment specifications, environmental control, and scalability. For further details or assistance, feel free to ask!

HOT PRODUCTS

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com