- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

- 2024-12-06

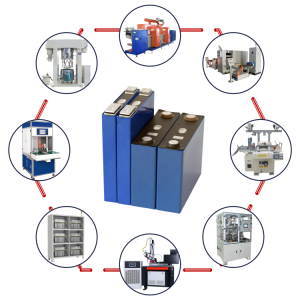

A battery fabrication plant is a facility dedicated to manufacturing energy storage systems such as lithium-ion batteries, solid-state batteries, or other advanced technologies. These plants play a vital role in industries like electric vehicles (EVs), renewable energy storage, and consumer electronics.

This article outlines the key components, processes, and considerations involved in setting up and operating a battery fabrication plant.

## Core Components of a Battery Production Line

1. Raw Material Preparation

- Involves the procurement and processing of active materials (e.g., lithium compounds, nickel, cobalt, and graphite) for electrodes.

- Facilities often include mixing and drying systems to prepare electrode slurries.

2. Electrode Manufacturing

- Processes include coating, calendaring, and cutting to create high-quality anodes and cathodes.

- Key Equipment:

- Electrode coating machines.

- Calendaring machines for thickness uniformity.

- Electrode cutting systems.

3. Cell Assembly

- The assembly process varies based on cell type (pouch, cylindrical, or prismatic):

- Stacking or Winding: Aligning anodes, cathodes, and separators.

- Electrolyte Filling: Injecting precise amounts of electrolyte.

- Key Equipment:

- Winding/stacking machines.

- Vacuum sealing machines.

- Automated electrolyte dispensers.

4. Formation and Aging

- Cells undergo initial charging and discharging cycles to stabilize internal chemistry.

- Equipment: Formation racks and environmental chambers for temperature-controlled cycling.

5. Battery Module and Pack Assembly

- Integrates individual cells into modules and packs with protection systems.

- Includes welding and assembly for electrical connections and thermal management systems.

6. Testing and Quality Control

- Ensures each cell, module, and pack meets safety and performance standards.

- Testing Methods: Electrical capacity, cycle life, thermal stability, and safety tests.

## Key Equipment in a Battery Fabrication Plant

● 1. Electrode Production Equipment

- Slurry Mixers: Uniformly mix active materials, binders, and solvents.

- Coating Machines: Apply active material slurry onto current collectors.

- Drying Ovens: Evaporate solvents after coating.

- Calendaring Machines: Compress electrodes for consistent thickness.

● 2. Cell Assembly Machines

- Electrode Cutting Machines: Precisely cut electrodes for stacking or winding.

- Stacking/Winding Machines: Assemble electrodes and separators into desired configurations.

- Electrolyte Filling Machines: Dispense electrolyte under controlled conditions.

- Vacuum Sealing Machines: Create airtight seals for pouch or prismatic cells.

● 3. Formation and Aging Systems

- Used to perform initial charging cycles and stabilize cell performance.

- Includes formation racks and aging cabinets.

● 4. Automation and Robotics

- Enhances efficiency and precision in assembly lines.

- Reduces human error in electrode handling, stacking, and sealing.

● 5. Safety and Environmental Controls

- Dry Rooms: Maintain low humidity for lithium-ion battery production.

- Air Filtration Systems: Minimize contamination.

- Explosion-Proof Chambers: Ensure safety during testing and handling flammable materials.

## Steps to Set Up a Battery Fabrication Plant

1. Define Product and Technology

- Determine the battery type (e.g., lithium-ion, solid-state, or flow battery) and application (e.g., EVs, grid storage).

2. Choose a Suitable Location

- Consider factors like proximity to raw materials, skilled labor, transportation, and regulatory compliance.

3. Design the Facility Layout

- Optimize for workflow efficiency, material handling, and safety compliance.

- Include dedicated zones for raw material storage, electrode production, cell assembly, and testing.

4. Invest in Advanced Equipment

- Prioritize precision and scalability to meet demand.

5. Implement Quality Control Systems

- Ensure every stage of production adheres to strict standards.

6. Train Personnel

- Skilled workers are critical for maintaining quality and operational efficiency.

7. Adopt Sustainable Practices

- Use renewable energy sources and minimize waste to align with environmental goals.

## Applications of Batteries Manufactured in Fabrication Plants

1. Electric Vehicles (EVs)

- Batteries for cars, buses, trucks, and two-wheelers.

2. Energy Storage Systems (ESS)

- Stationary batteries for solar and wind energy storage.

3. Consumer Electronics

- Powering smartphones, laptops, and wearable devices.

4. Aerospace and Defense

- High-performance batteries for satellites and military applications.

## Challenges in Battery Fabrication Plants

1. Raw Material Sourcing

- Dependence on critical materials like lithium, cobalt, and nickel.

2. Cost Management

- Balancing equipment costs and production scalability.

3. Environmental Regulations

- Complying with stringent rules for emissions and waste management.

4. Technological Advancements

- Staying competitive requires continuous innovation.

5. Energy Efficiency

- Optimizing energy use in production processes.

## Conclusion

A battery fabrication plant is a cornerstone of the energy transition, enabling advancements in electric mobility, renewable energy storage, and portable electronics. By leveraging cutting-edge equipment, automation, and quality control, manufacturers can produce reliable, high-performance batteries to meet growing global demand. Strategic planning, skilled personnel, and sustainable practices are critical for success in this rapidly evolving industry.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com