- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

- 2025-08-19

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 200000 square foot and more than 230 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

A battery manufacturing plant is a specialized facility designed to produce batteries at scale, catering to industries such as electric vehicles (EVs), renewable energy storage, consumer electronics, and industrial applications. These plants integrate advanced manufacturing technologies, automation, and sustainable practices to ensure highquality battery production while meeting global demand.

Below is a detailed overview of battery manufacturing plants, including their design, operations, innovations, challenges, and best practices.

●1. Overview of Battery Manufacturing Plants

Battery manufacturing plants are largescale facilities that house the equipment, processes, and personnel required to produce batteries efficiently. They often operate under the term gigafactories when they have extremely high production capacities (e.g., producing tens of gigawatthours of batteries annually).

Key characteristics:

Highthroughput manufacturing with minimal defects.

Integration of automation, robotics, and data analytics for efficiency and quality assurance.

Focus on sustainability, including waste reduction, energy efficiency, and material recycling.

●2. Components of a Battery Manufacturing Plant

A. Material Preparation Area

This section handles the preparation of raw materials for electrode production.

#Processes:

Mixing active materials, binders, and conductive agents into slurry.

Coating electrodes onto metal foils (aluminum for cathodes, copper for anodes).

Drying and calendering electrodes to achieve uniform thickness and density.

#Equipment:

Mixing machines (planetary mixers, highshear mixers).

Coating machines (slot die coaters, doctor blade coaters).

Drying ovens (tunnel dryers, vacuum dryers).

Calendering machines (rolltoroll calenders).

B. Electrode Processing Area

This section focuses on cutting, shaping, and tab welding the electrodes.

#Processes:

Cutting electrodes into specific dimensions.

Attaching current collectors (tabs) to electrodes for electrical connections.

#Equipment:

Cutting machines (laser cutters, punch cutters).

Tab welding machines (ultrasonic welders, laser welders).

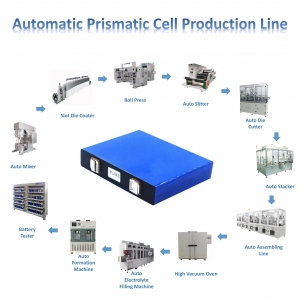

C. Cell Assembly Area

This section involves assembling the electrodes, separator, and casing into a complete cell.

#Processes:

Stacking or winding cathode, separator, and anode layers.

Placing the electrode stack into a metal casing (prismatic cells) or pouch (pouch cells).

Sealing the casing or pouch to prevent electrolyte leakage.

#Equipment:

Stacking machines or winding machines.

Casing machines (prismatic casing machines, pouch sealing machines).

Sealing machines (laser welders, heat sealers).

D. Electrolyte Filling Area

This section handles the injection of electrolyte into the battery cell.

#Processes:

Filling the cell with electrolyte under controlled conditions.

Forming the solidelectrolyte interphase (SEI) layer through initial chargedischarge cycles.

#Equipment:

Electrolyte filling machines (vacuumassisted systems, precision dispensers).

Formation chambers (cycling testers).

E. Testing and Quality Control Area

This section evaluates the performance and safety of the battery.

#Processes:

Conducting formation tests to activate the battery.

Measuring capacity, internal resistance, cycle life, and safety parameters.

#Equipment:

Formation testers.

Capacity testers.

Safety testers (thermal abuse testers, nail penetration testers).

F. Recycling Area

This optional section focuses on recovering valuable materials from spent batteries.

#Processes:

Shredding and sorting spent batteries.

Extracting and purifying materials such as lithium, cobalt, and nickel.

#Equipment:

Shredding machines (hammer mills, granulators).

Sorting machines (magnetic separators, air classifiers).

Refining equipment (hydrometallurgical and pyrometallurgical systems).

●3. Operations in a Battery Manufacturing Plant

A. Automation and Robotics

Robots and collaborative robots (cobots) perform repetitive tasks with high precision.

Conveyor systems and AGVs (autonomous guided vehicles) streamline material handling.

B. Digitalization

IoTenabled machines provide realtime data monitoring and predictive maintenance.

AIdriven algorithms optimize process parameters and reduce defects.

C. Energy Management

Renewable energy sources (e.g., solar, wind) power the plant to reduce carbon footprint.

Energyefficient machinery minimizes operational costs.

D. Waste Reduction

Closedloop systems recycle solvents and other chemicals used in production.

Minimal waste generation through precise material handling and reuse.

●4. Innovations in Battery Manufacturing Plants

A. SolidState Battery Production

Development of fabrication lines for solidstate batteries, which require new techniques for electrolyte deposition and cell assembly.

B. Modular Design

Modular production lines allow for easy reconfiguration to accommodate different battery types and chemistries.

C. Sustainable Practices

Ecofriendly designs minimize waste and energy consumption during production.

Recycling facilities integrated into the plant recover valuable materials from spent batteries.

D. Advanced Materials

Research into new cathode, anode, and electrolyte materials (e.g., siliconbased anodes, solidstate electrolytes) drives innovation in production processes.

●5. Challenges in Battery Manufacturing Plants

A. Precision Requirements

Achieving submicron accuracy in electrode alignment and thickness control is challenging.

B. Cost

High initial investment in advanced machinery and infrastructure can be a barrier for smaller manufacturers.

C. Scalability

Balancing high throughput with quality control is difficult, especially for emerging battery technologies.

D. Safety

Ensuring safe handling of hazardous materials (e.g., electrolytes) during production is critical.

E. Supply Chain

Dependence on critical raw materials (e.g., lithium, cobalt) and geopolitical factors can disrupt production.

●6. Market Trends and Future Outlook

A. Growing Demand for EVs

The rapid adoption of electric vehicles drives demand for highthroughput battery manufacturing plants capable of producing large quantities of prismatic and pouch batteries.

B. Gigafactories

Largescale battery manufacturing plants (gigafactories) rely on highly automated and scalable fabrication lines to meet global demand.

C. Customization

Manufacturers are increasingly seeking customized manufacturing plants tailored to specific chemistries, formats, and applications.

D. Advanced Materials

Research into new battery chemistries (e.g., sodiumion, solidstate) requires specialized production equipment and processes.

●7. Best Practices for Battery Manufacturing Plants

A. Process Optimization

Continuously monitor and improve manufacturing processes to reduce defects and increase yield.

B. Quality Control

Implement rigorous testing protocols to ensure battery performance, safety, and longevity.

C. Sustainability

Adopt ecofriendly practices, such as using renewable energy sources and recycling materials.

D. Safety Standards

Adhere to industry safety standards and regulations to protect workers and the environment.

E. Collaboration

Collaborate with suppliers, researchers, and customers to stay ahead of technological advancements and market demands.

●8. Importance of Battery Manufacturing Plants

Battery manufacturing plants are essential for meeting the growing demand for highperformance batteries across various industries. From material preparation to final testing, these plants integrate advanced technologies such as automation, digitalization, and sustainability to ensure efficient, reliable, and safe production.

●9. Conclusion

Battery manufacturing plants are the backbone of modern battery production, enabling the fabrication of highquality batteries for a wide range of applications. By leveraging innovations in automation, digitalization, and sustainable practices, manufacturers can optimize their production processes, reduce costs, and accelerate the adoption of advanced battery technologies.

If you're involved in designing, operating, or investing in battery manufacturing plants, consider factors such as plant layout, automation level, and technological advancements. For further details or assistance, feel free to ask!

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com