- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

- 2024-10-22

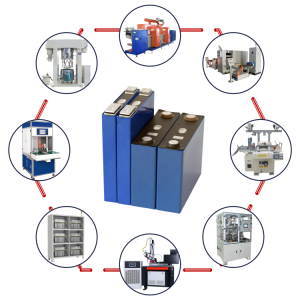

A cell assembly line is a specialized production line designed for the assembly of battery cells, particularly lithium-ion batteries. This line integrates various processes to efficiently manufacture cells that meet high-performance and safety standards for applications in electric vehicles, consumer electronics, and energy storage systems.

● Key Components of a Battery Production Line

1. Material Preparation

- Active Materials: Precursors for the anode and cathode, typically graphite and lithium compounds, are prepared.

- Separators: Materials like polyethylene or polypropylene are processed to create separators that prevent short circuits.

2. Electrode Fabrication

- Coating: Electrode slurries are coated onto metal foils using precision coating machines.

- Drying: Coated electrodes are dried to remove solvents and achieve optimal material properties.

- Calendering: The dried electrodes are compressed to enhance density and conductivity.

3. Electrode Cutting

- The dried and processed electrodes are cut into specific sizes and shapes tailored for the battery design.

4. Cell Assembly

- Layer Stacking: The anode, separator, and cathode are stacked or wound together in the correct order.

- Electrolyte Filling: The electrolyte is injected into the assembly to saturate the electrodes.

- Sealing: The assembly is sealed within a casing, which may be cylindrical, prismatic, or pouch-type.

5. Formation and Aging

- Formation Cycling: Initial charge and discharge cycles activate the battery chemistry.

- Aging: Cells are aged in controlled environments to stabilize performance over time.

6. Testing and Quality Control

- Cells undergo rigorous testing for capacity, voltage, internal resistance, and safety to ensure they meet specifications.

7. Packaging and Shipping

- Approved cells are packaged for shipment to customers or for integration into battery packs.

● Advantages of a Dedicated Cell Assembly Line

1. Efficiency: Streamlined processes and automation can significantly enhance production speed and reduce labor costs.

2. Quality Control: Integrated testing at various stages helps ensure consistent quality and compliance with safety standards.

3. Flexibility: Assembly lines can be adapted to produce different battery chemistries and designs, allowing manufacturers to meet changing market demands.

4. Scalability: Dedicated lines can be scaled up or down based on production needs, accommodating fluctuations in demand.

● Applications of Cell Assembly Lines

- Electric Vehicles (EVs): Critical for producing high-capacity battery packs for EVs, enhancing performance and range.

- Consumer Electronics: Used for manufacturing batteries for smartphones, laptops, and other portable devices.

- Energy Storage Systems: Essential in the production of batteries used in renewable energy applications, such as solar and wind storage.

● Conclusion

A cell assembly line plays a crucial role in the efficient production of high-performance battery cells. With advancements in technology and increasing demand for energy storage solutions, these lines are essential in ensuring that manufacturers can deliver reliable and innovative battery products to meet diverse market needs. As the industry evolves, the importance of optimizing cell assembly processes will continue to grow, contributing to the development of next-generation energy solutions.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com