- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

- 2024-11-08

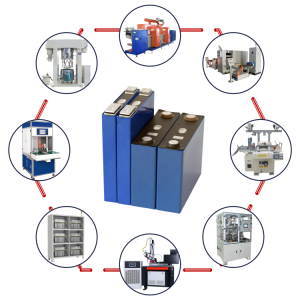

A prismatic cell assembly line is a dedicated production line designed to manufacture prismatic lithium-ion cells, which are commonly used in applications requiring high energy density and compact designs, such as electric vehicles (EVs), renewable energy storage, and consumer electronics. Prismatic cells feature a rectangular casing, which maximizes space efficiency, making them ideal for battery packs that need to fit within confined spaces.

● Key Stages in a Prismatic Cell Manufacturing

1. Electrode Preparation

- Mixing and Coating: The active materials (typically lithium compounds for the cathode and graphite or silicon for the anode) are mixed with binders and conductive additives. The resulting slurry is coated onto thin metal foils (aluminum for the cathode and copper for the anode).

- Drying and Calendering: The coated electrodes are dried to remove solvents and then passed through a calendering machine to achieve the desired thickness and density, enhancing the electrochemical performance of the electrodes.

2. Electrode Cutting and Notching

- Precision Cutting: Electrodes are cut to specific dimensions for assembly. High precision is crucial to ensure the uniformity and quality of the final cell.

- Notching: This process shapes the electrode edges to allow for proper stacking or winding. Notching reduces the risk of internal short circuits and ensures efficient space utilization within the prismatic cell.

3. Stacking or Winding Process

- Stacking: Prismatic cells are typically assembled by stacking individual layers of anode, separator, and cathode in sequence. Robotic arms or automated machines carefully stack the layers to ensure consistent alignment.

- Z-Folding: In some prismatic cells, the separator is folded in a zig-zag fashion to create a multi-layered structure with alternating anode and cathode layers, maintaining proper separation and maximizing cell capacity.

4. Electrolyte Filling and Impregnation

- Vacuum Filling: The electrolyte is injected into the cell casing under vacuum conditions to ensure complete penetration and to avoid the formation of air pockets, which could degrade cell performance.

- Impregnation: After electrolyte filling, the cell is allowed to sit for a set duration, allowing the electrolyte to fully impregnate the electrodes and enhance ion conductivity.

5. Sealing Process

- Heat Sealing: The prismatic cell casing, usually made of aluminum or another durable material, is heat-sealed to prevent any leakage of the electrolyte.

- Laser Welding: For cells that require added structural integrity, laser welding can be used to create a strong, airtight seal, which is especially important for applications in high-vibration environments like electric vehicles.

6. Formation and Aging

- Formation Cycling: The newly assembled cells undergo initial charge and discharge cycles to activate the electrochemical materials. This is a critical step to stabilize the battery’s capacity and voltage.

- Aging Process: Cells are stored for a specific period under controlled temperature and humidity to monitor capacity retention, internal resistance, and overall performance stability before being cleared for final testing and packaging.

7. Final Testing and Quality Control

- Capacity Testing: Each cell is tested to ensure it meets the required capacity specifications.

- Safety Tests: Cells are subjected to a series of tests for voltage consistency, internal resistance, and thermal stability to verify that they meet safety and reliability standards.

● Equipment Used in a Prismatic Cell Assembly Line

1. Mixing and Coating Machines: Mixes and applies the electrode materials onto metal foils with uniform thickness.

2. Calendering Machines: Compresses the electrode layers for consistent density.

3. Cutting and Notching Machines: Cuts electrodes to precise dimensions and shapes.

4. Stacking Machines: Automates the stacking process to ensure accurate layer alignment.

5. Vacuum Filling Machines: Used to inject the electrolyte under vacuum to ensure full impregnation.

6. Heat Sealing and Welding Machines: Seal the prismatic cells to prevent leakage and enhance durability.

7. Formation and Testing Equipment: Performs the initial charge/discharge cycles and quality checks.

● Advantages of Prismatic Cell Assembly Lines

1. High Energy Density: Prismatic cells are space-efficient, offering high energy capacity within a compact form factor.

2. Customizable Size: The assembly line can be adapted to produce cells in various sizes, allowing manufacturers to customize cells to meet specific design requirements.

3. Improved Safety: Enhanced sealing techniques (such as heat-sealing and laser welding) reduce the risk of electrolyte leakage and improve safety.

4. High Automation Potential: Prismatic cell assembly lines are highly automated, improving production efficiency and ensuring quality consistency.

● Applications of Prismatic Cells

1. Electric Vehicles (EVs): Prismatic cells are widely used in EV battery packs due to their high energy density and efficient form factor.

2. Energy Storage Systems: They are also popular in stationary energy storage applications, providing reliable power storage in renewable energy setups.

3. Consumer Electronics: Some prismatic cells are used in portable devices where space efficiency and high capacity are essential.

● Challenges and Considerations

1. Cost of Equipment: Prismatic cell assembly lines require high-precision and automated equipment, resulting in significant initial investment costs.

2. Handling Sensitivity: Prismatic cells need precise handling to avoid physical stress, which can compromise cell integrity.

3. Thermal Management: Prismatic cells are sensitive to overheating; effective thermal management is necessary, especially in high-energy applications like EVs.

● Conclusion

A prismatic cell assembly line is essential for producing high-capacity, space-efficient batteries tailored for industries such as automotive, consumer electronics, and renewable energy storage. The streamlined processes of electrode preparation, stacking, filling, sealing, and testing ensure that prismatic cells meet the highest standards of quality, safety, and performance. As the demand for reliable energy storage grows, prismatic cell assembly lines will continue to be at the forefront of battery manufacturing innovation.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com