- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

- 2025-06-17

Xiamen Tmax Battery Equipments Limited was set up as a manufacturer in 1995, dealing with lithium battery equipments, technology, etc. We have total manufacturing facilities of around 200000 square foot and more than 230 staff. Owning a group of experie-nced engineers and staffs, we can bring you not only reliable products and technology, but also excellent services and real value you will expect and enjoy.

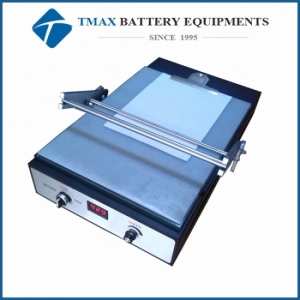

A lab film coating machine is a specialized piece of equipment used in research and development (R&D) environments to apply thin, uniform coatings onto various substrates. These machines are designed for smallscale experiments, material testing, and prototype development. They play a critical role in industries such as battery manufacturing, pharmaceuticals, electronics, and advanced materials research.

Lab film coating machines allow researchers to test new materials, optimize coating processes, and evaluate the performance of coated films before scaling up to industrial production. Below is a detailed overview of lab film coating machines, including their design, functionality, advantages, challenges, and applications.

●1. What Is a Lab Film Coating Machine?

A lab film coating machine is a compact, precisionengineered device that applies liquid or solid coatings onto substrates such as metal foils, polymer films, papers, or glass. It typically uses techniques like slot die coating, doctor blade coating, spin coating, or spray coating to achieve precise control over thickness, uniformity, and surface quality.

Key features of lab film coating machines:

Small footprint suitable for laboratory settings.

Adjustable parameters for flexibility in experimentation.

Integration with analytical tools for realtime monitoring.

●2. Key Components of a Lab Film Coating Machine

The main components of a lab film coating machine include:

A. Coating Head

Mechanism for applying the coating material onto the substrate.

Can be a slot die, doctor blade, or other precision tool depending on the application.

B. Substrate Handling System

Device to hold or move the substrate during the coating process.

May include manual or automated stages for precise positioning.

C. Material Delivery System

Pumps and reservoirs to supply the coating material (e.g., slurries, polymers, adhesives) to the coating head.

D. Drying/Curing System

Oven, heater, or UV curing unit to dry or cure the coated layer after application.

E. Thickness Measurement System

Sensors (e.g., laser, micrometer) to measure the thickness of the coated layer in realtime.

F. Control System

User interface or software to adjust parameters such as speed, pressure, temperature, and flow rate.

●3. Operation of a Lab Film Coating Machine

The operation of a lab film coating machine involves the following steps:

1. Material Preparation:

The coating material (e.g., slurry, adhesive, polymer) is prepared and loaded into the delivery system.

2. Coating Process:

The substrate is positioned under the coating head, and the material is applied using the chosen method (e.g., slot die, doctor blade).

3. Drying/Curing Process:

The coated layer is dried or cured to remove solvents or activate bonding.

4. Evaluation:

The coated film is analyzed for thickness, uniformity, adhesion, and other properties.

5. Cleanup:

The machine is cleaned to prevent contamination between experiments.

Film Coating Machine

Lab film coating machines are essential tools for R&D because they enable researchers to:

A. Test New Materials

Evaluate the performance of experimental coatings, slurries, or polymers.

B. Optimize Processes

Finetune coating parameters such as thickness, speed, and temperature for optimal results.

C. Develop Prototypes

Create smallscale prototypes for functional testing before scaling up to industrial production.

D. Ensure Precision

Achieve high levels of accuracy and repeatability in coating experiments.

●5. Applications of Lab Film Coating Machines

A. Battery Research

Used to coat active materials onto metal foils (e.g., aluminum cathodes, copper anodes) for lithiumion batteries.

Ideal for developing and testing new electrode formulations.

B. Pharmaceutical Industry

Applied in the production of drugcoated films or tablets for controlled release.

C. Electronics

Used to deposit functional layers onto substrates for flexible displays, sensors, or printed circuits.

D. Advanced Materials

Employed in the development of nanomaterials, composites, and coatings for aerospace, automotive, and construction applications.

E. Packaging

Used to apply barrier coatings, laminating adhesives, or functional layers onto films and papers.

●6. Advantages of Lab Film Coating Machines

| Advantage | Description |

|||

| Precision | Achieves highly accurate and repeatable coatings for reliable experimentation. |

| Flexibility | Adjustable parameters allow testing of various materials and coating methods. |

| CostEffectiveness | Smaller scale and lower material usage reduce costs compared to industrial systems. |

| Compact Design | Fits easily into laboratory environments with limited space. |

| Integration with Analytics | Compatible with analytical tools for realtime monitoring and data collection. |

●7. Challenges in Using Lab Film Coating Machines

A. Limited Throughput

Designed for smallscale experiments, so throughput is lower than industrial systems.

B. Material Compatibility

Certain materials may require specific adjustments to achieve optimal results.

C. Calibration Sensitivity

Precise calibration is essential to ensure consistent and accurate coatings.

D. Maintenance Requirements

Regular cleaning and maintenance are necessary to avoid crosscontamination between experiments.

●8. Types of Lab Film Coating Machines

A. Slot Die Coater

Uses a slot die mechanism to apply liquid coatings with precise thickness control.

Ideal for battery electrode coatings and polymer films.

B. Doctor Blade Coater

Employs a stationary blade to spread the coating material onto the substrate.

Suitable for thick coatings and highviscosity materials.

C. Spin Coater

Spins the substrate at high speeds to evenly distribute the coating material.

Commonly used in semiconductor and thinfilm applications.

D. Spray Coater

Atomizes the coating material and sprays it onto the substrate for even distribution.

Useful for complex geometries or porous substrates.

●9. Market Trends and Future Outlook

A. Growing R&D Investments

Increasing focus on advanced materials, energy storage, and electronics drives demand for lab film coating machines.

B. Automation and Digitalization

Integration of IoT, AI, and robotics enhances precision, efficiency, and data collection in labscale coating processes.

C. Sustainability

Development of ecofriendly materials and reduced waste in coating experiments.

D. Modular Systems

Modular designs allow easy customization for diverse research needs.

●10. Conclusion

Lab film coating machines are indispensable tools for researchers working in material science, battery technology, pharmaceuticals, and electronics. Their ability to provide precise, repeatable coatings on a small scale makes them ideal for experimentation and prototyping.

If you're planning to acquire or operate a lab film coating machine, carefully consider factors such as material compatibility, desired coating method, and scalability potential. For further details or assistance, feel free to ask!

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com