- Battery Manufacturing Equipment

- Battery Laboratory Assembly Equipment

- Battery Pack Assembly Equipment

- Sodium Ion Battery Manufacturing Equipment

- Solid State Cell Production Line

- Dry Electrode Assembly Equipment

- Supercapacitor Assembly Equipment

- Perovskite Solar Cell Lab Equipment

- Li ion Battery Materials

- Ni / Al / Cu Metal Foam

- Customized Electrode

- Cathode Active Materials

- Anode Active Materials

- Coin Cell Parts

- Lithium Chip

- Cylindrical Cell Parts

- Battery Current Collectors

- Battery Conductive Materials

- Electrolyte

- Battery Binder

- Separator and Tape

- Aluminum Laminate Film

- Nickel Strip/Foil

- Battery Tabs

- Graphene Materials

- Cu / Al / Ni / Stainless steel Foil

- Battery Laboratory Equipment

- Li ion Battery Tester

- Battery Safety Tester

- Material Characterization Tester

- Rolling Press Machine

- Electrode Mixer

- Coin Cell Crimping Machine

- Coin Cell Electrode Disc Punching

- Pouch Cell Sealing Machine

- Pouch Cell Stacking Machine

- Pouch Cell Forming Machine

- Pouch Cell Ultrasonic Welder

- Pouch Cell Electrode Die Cutter

- Cylinder Cell Sealing Machine

- Cylinder Cell Grooving Machine

- Electrode Slitting Machine

- Cylinder Cell Winding Machine

- Cylinder Cell Spot Welding Machine

- Electrolyte Filling

- Type Test Cell

- Other Battery Making Machine

- NMP Solvent Treatment System

- Vacuum Glove Box

- Coating Machine

- Lab Furnaces

- Ball Mill

- Laboratory Press

- Laboratory Equipment

- Press Equipment

- 2023-04-13

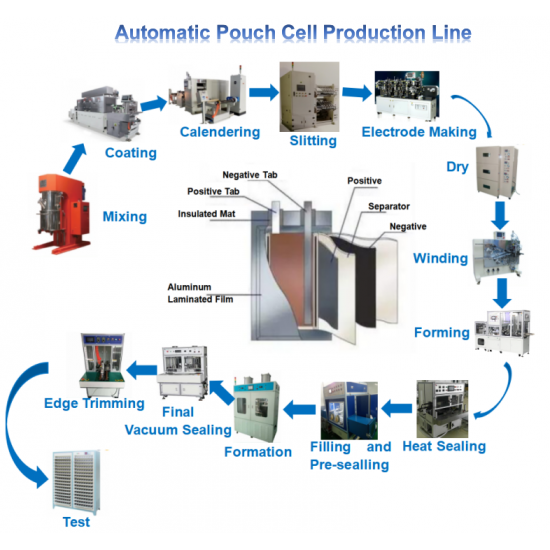

Here's a brief overview of the equipment involved in a typical pouch cell assembly line:

- Battery coating machine: Used to coat the cathode and anode with the active material.

- Electrode slitting machine: Used to cut the coated cathode and anode into strips of a desired width.

- Electrode stacking machine: Used to stack the cathode, separator, and anode strips together in the desired order to form the electrode assembly.

- Pouch cell winder: Used to roll the electrode assembly into a cylindrical shape.

- Tab welding machine: Used to weld the tabs onto the electrode assembly to provide electrical contacts.

- Formation machine: Used to form the electrode assembly by charging and discharging it repeatedly.

- Cell cutting machine: Used to cut the electrode assembly into individual cells.

- Cell stacking machine: Used to stack the individual cells together to form the final battery pack.

- Battery pack testing machine: Used to test the performance of the final battery pack.

Production Process

- Slitting: The first step in the production of pouch cells is the slitting of the electrode material into the required dimensions.

- Coating: The electrode material is then coated with a thin layer of active material.

- Drying: The coated electrode material is dried to remove any excess solvent.

- Calendering: The electrode material is then calendered to the required thickness and density.

- Slitting: The calendered electrode material is slit to the required width for use in the cell.

- Lamination: The electrode material is laminated to a separator material, and the resulting electrode/separator laminate is rolled onto a spool.

- Winding: The electrode/separator laminate spool is then used to wind the anode and cathode of the pouch cell.

- Stacking: The wound anode and cathode are stacked and placed in a pouch.

- Sealing: The pouch is sealed, and the electrolyte is added to complete the assembly.

- Formation: The cell undergoes a formation process to stabilize the capacity and performance of the battery.

- Benefits

High Precision: Pouch cell assembly lines are designed to produce batteries with consistent quality and performance.

High Efficiency: The automated nature of pouch cell assembly lines results in a high rate of production and minimal waste.

Customizable: The pouch cell assembly line can be tailored to meet specific production requirements, including varying sizes and capacities.

Flexibility: Pouch cell assembly lines are capable of producing a wide range of battery chemistries, making them versatile and adaptable to changing market demands.

Considerations

- Safety: The production of lithium-ion batteries can pose a safety risk due to the flammable electrolyte used. Thus, pouch cell assembly lines must be designed with safety features, such as fire suppression systems and emergency shutdown procedures.

- Quality Control: Pouch cell assembly lines must have a robust quality control system in place to ensure that each battery produced meets the required standards.

- Maintenance: Regular maintenance and calibration of the equipment are critical to the efficient and safe operation of the assembly line.

In conclusion, pouch cell assembly lines are a crucial component of the lithium-ion battery production process. With their high precision, efficiency, and flexibility, they enable the production of high-quality batteries at a large scale. However, careful consideration of safety, quality control, and maintenance is necessary to ensure the safe and efficient operation of the assembly line.

-

Automatic Cylinderical Battery Electrode Winding Machine

Read More

Automatic Cylinderical Battery Electrode Winding Machine

Read More

-

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

100-200L Double Planetary Vacuum Mixing Machine for Lithium Battery Slurry

Read More

-

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

Large Heating Roller Press Machine Calender For Li ion Battery Production Line

Read More

-

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

Large 3 Rollers Battery Electrode Film Intermittent Coating Machine for Pilot Production Line

Read More

-

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

512 Channel 5V3A Battery Grading Machine/Battery Charge Discharge Machine Tester

Read More

English▼

English▼

David@battery-equipments.com

David@battery-equipments.com